The Top Benefits Of Using A Capping Machine For Your Packaging Needs

Are you looking to streamline your packaging process and improve efficiency in your business operations? Look no further than the use of a capping machine. In this article, we will explore the top benefits of utilizing a capping machine for your packaging needs, from time and labor savings to improved product quality. Discover how this innovative technology can revolutionize your packaging process and take your business to the next level.

- Streamlining the Packaging Process with a Capping Machine

In the fast-paced world of manufacturing and packaging, efficiency is key. One essential tool that can help streamline the packaging process is a capping machine. These innovative machines offer a range of benefits that can have a significant impact on your packaging operation.

One of the primary advantages of using a capping machine is its ability to automate the capping process. Traditionally, capping bottles and containers was a labor-intensive task that required a significant amount of time and manpower. With a capping machine, this process is automated, allowing for faster and more consistent capping of products. This not only saves time but also reduces the risk of human error, ensuring that each product is sealed correctly every time.

Another major benefit of using a capping machine is its versatility. These machines are designed to work with a wide range of bottle sizes, shapes, and materials, making them suitable for a variety of packaging needs. Whether you are capping plastic bottles, glass jars, or metal containers, a capping machine can be easily adjusted to accommodate different packaging requirements. This flexibility is especially valuable for manufacturers who produce a range of products and need a versatile solution for their capping needs.

In addition to automating and streamlining the capping process, capping machines also offer improved efficiency and productivity. By reducing the time and labor required for capping, these machines free up resources that can be allocated to other areas of the packaging operation. This can result in increased output and higher production rates, ultimately leading to cost savings and improved overall efficiency.

Furthermore, capping machines are designed to provide a secure and reliable seal on each product, ensuring that they remain fresh and tamper-proof during storage and transport. This is especially important for industries that produce perishable goods or products that require airtight sealing to maintain their quality. With a capping machine, manufacturers can trust that their products will be properly sealed and protected, reducing the risk of spoilage or contamination.

Overall, investing in a capping machine for your packaging operation can have a significant impact on efficiency, productivity, and product quality. These machines offer a range of benefits, including automation, versatility, efficiency, and reliability, making them an essential tool for any manufacturer looking to streamline their packaging process. By incorporating a capping machine into your operation, you can enhance the efficiency of your packaging process, improve product quality, and ultimately, boost your bottom line.

- Ensuring Efficiency and Consistency in Packaging

Packaging plays a crucial role in the success of any product, from protecting its contents to creating an attractive presentation for consumers. In order to achieve efficiency and consistency in packaging, many businesses turn to the use of capping machines. These automated devices are designed to securely seal containers with caps or lids, ensuring that products are properly protected and ready for distribution.

One of the top benefits of using a capping machine for your packaging needs is its ability to streamline the packaging process. By automating the task of applying caps or lids to containers, capping machines can significantly reduce the time and labor required for packaging, allowing businesses to increase their throughput and meet growing demand. This increased efficiency not only saves time and money, but also helps businesses maintain a competitive edge in the market.

In addition to efficiency, capping machines also offer consistency in packaging. Manual capping can lead to variations in torque, leading to improperly sealed containers that may leak or become contaminated. Capping machines are designed to apply caps with precise torque control, ensuring that each container is sealed to the same specifications every time. This consistency not only improves the overall quality of the packaging but also helps to maintain the integrity of the product inside.

Furthermore, capping machines are versatile and can accommodate a wide range of container sizes and shapes. Whether you are packaging bottles, jars, or tubes, capping machines can be easily adjusted to accommodate different types of caps and containers, making them a versatile solution for a variety of packaging needs. This flexibility allows businesses to adapt to changing market demands and expand their product offerings without having to invest in additional equipment.

Another key benefit of using a capping machine is its ability to reduce product waste. Improperly sealed containers can lead to product spoilage or contamination, resulting in significant losses for businesses. Capping machines ensure that each container is properly sealed, reducing the risk of product spoilage and waste. This not only helps businesses save money but also improves their reputation with customers by delivering products that are consistently high quality.

In conclusion, capping machines offer a range of benefits for businesses looking to improve efficiency and consistency in their packaging processes. From streamlining the packaging process to maintaining product quality and reducing waste, capping machines are a valuable investment for any business looking to enhance their packaging operations. By utilizing the latest technology in capping machines, businesses can stay ahead of the competition and meet the demands of an ever-changing market.

- Enhancing Product Shelf Life and Quality

In today's fast-paced and competitive market, it is essential for businesses to continually strive to improve their product shelf life and quality. One key tool that can help with this is a capping machine. By investing in a capping machine for your packaging needs, you can benefit in a variety of ways, all of which contribute to enhancing the shelf life and quality of your products.

First and foremost, a capping machine helps to ensure that your product is securely sealed, preventing any contaminants from entering the package. This is crucial in maintaining the freshness and quality of your product, as even the smallest exposure to air or other external elements can lead to degradation. With a capping machine, you can trust that your products will remain intact and safe for consumption for an extended period of time.

Furthermore, a capping machine allows for consistent and precise sealing of your products, which is essential for maintaining uniformity and quality. With manual capping, there is always the risk of human error, leading to inconsistent seals that can compromise the integrity of the product. A capping machine eliminates this risk by ensuring that each package is sealed with the same level of accuracy and precision, resulting in a higher quality final product.

In addition to improving the shelf life and quality of your products, a capping machine also offers time and cost-saving benefits. By automating the capping process, you can significantly reduce the amount of time and labor required to seal your products, allowing your employees to focus on other tasks that require their attention. This not only increases efficiency but also helps to lower production costs in the long run.

Moreover, a capping machine can help to enhance the overall appearance of your products, making them more appealing to consumers. With a neatly sealed package, your products will look professional and well-presented, which can attract more customers and lead to increased sales. In today's competitive market, it is essential to stand out from the competition, and investing in a capping machine can help you do just that.

Overall, the benefits of using a capping machine for your packaging needs are clear. From enhancing product shelf life and quality to improving efficiency and lowering production costs, a capping machine is a valuable tool for any business looking to improve their packaging process. By investing in a capping machine, you can ensure that your products remain fresh, safe, and appealing to customers, ultimately leading to increased success and growth for your business.

- Meeting Industry Standards and Regulations

In today’s fast-paced and competitive business environment, meeting industry standards and regulations is crucial for any company looking to remain relevant and successful in their respective market. When it comes to packaging needs, utilizing a capping machine can be a game-changer in ensuring that your products adhere to these standards and regulations.

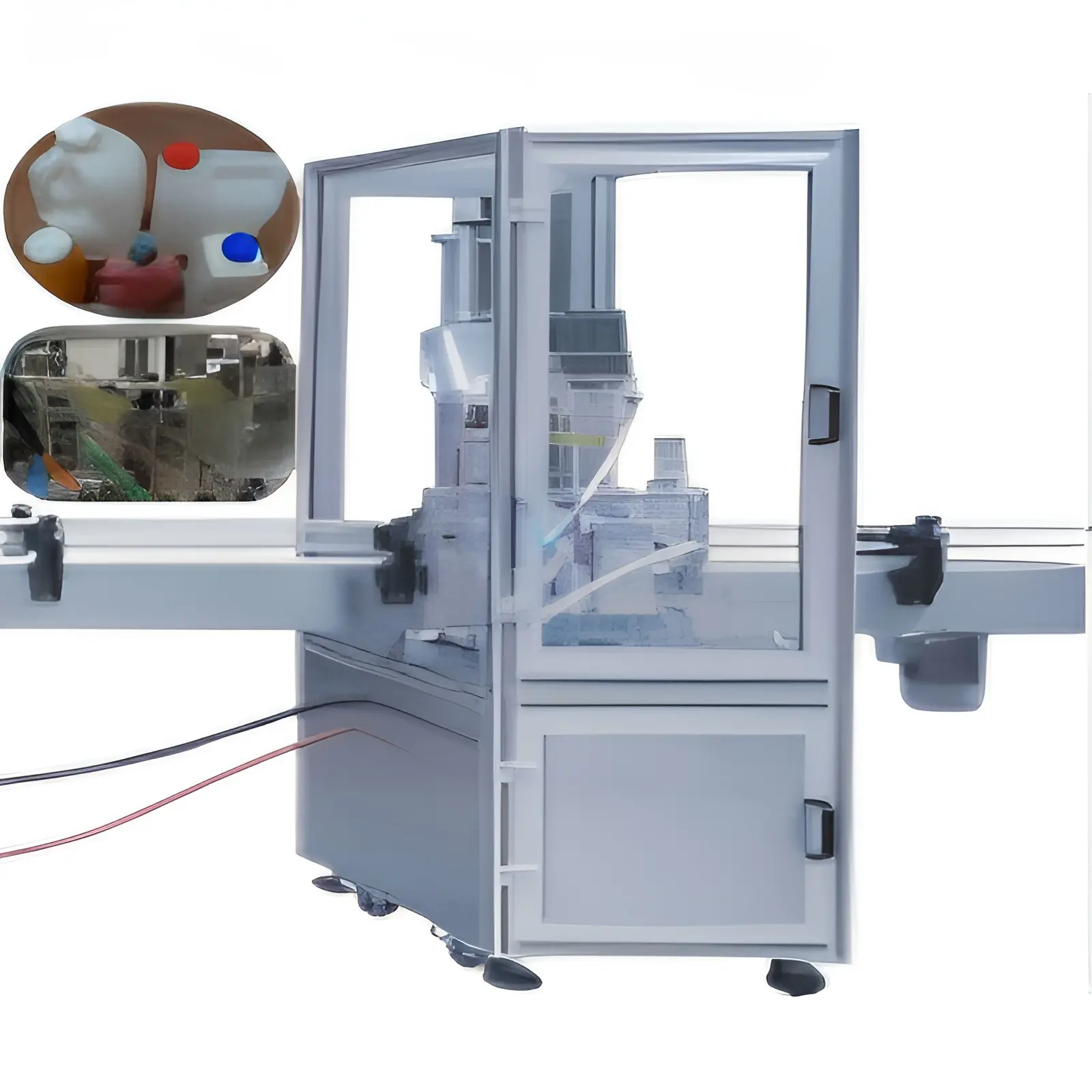

A capping machine is a piece of equipment that is specifically designed to securely seal containers with caps or lids. These machines come in various types, including automatic capping machines, semi-automatic capping machines, and handheld capping machines. Regardless of the type of capping machine you choose, one thing is for certain – they can significantly streamline your packaging process and help you meet industry standards and regulations.

One of the top benefits of using a capping machine for your packaging needs is the consistency and reliability it offers. Manual capping methods are often prone to errors and inconsistencies, which can result in subpar packaging that does not meet industry standards. With a capping machine, you can ensure that each container is sealed perfectly every time, with the right amount of torque and precision. This level of consistency not only enhances the overall quality of your packaging but also helps you meet the strict standards set forth by regulatory bodies.

Furthermore, capping machines are often equipped with features that can help you comply with specific industry regulations. For example, many capping machines are designed to handle different types of caps and containers, including child-resistant caps and tamper-evident seals. These features are essential for industries such as pharmaceuticals, healthcare, and food and beverage, where safety and security are of the utmost importance. By using a capping machine that is specifically tailored to your industry’s requirements, you can rest assured that your packaging meets all necessary regulations.

Another key benefit of using a capping machine is the efficiency it brings to your packaging process. Manual capping can be time-consuming and labor-intensive, especially when dealing with large volumes of products. A capping machine automates this process, allowing you to cap containers quickly and efficiently, saving you time and labor costs. This increased efficiency not only improves your overall productivity but also helps you meet tight deadlines and keep up with consumer demand.

In conclusion, utilizing a capping machine for your packaging needs can offer a host of benefits, from ensuring consistency and reliability to helping you meet industry standards and regulations. Whether you are in the pharmaceutical, healthcare, food and beverage, or any other industry that requires precise and secure packaging, a capping machine is a valuable investment that can significantly improve your packaging process. By choosing the right capping machine for your specific needs, you can streamline your operations, enhance the quality of your products, and stay ahead of the competition.

- Saving Time and Money in Packaging Operations

In today's fast-paced business world, efficiency is key when it comes to packaging operations. That's why more and more companies are turning to capping machines to help streamline their processes and save both time and money. Capping machines are automated devices that are designed to securely seal a wide variety of packaging types, including bottles, jars, tubes, and containers. These machines can significantly increase the speed and accuracy of the packaging process, leading to higher productivity and decreased labor costs.

One of the top benefits of using a capping machine is the time-saving aspect. Manual capping can be a time-consuming and tedious task, especially when dealing with large quantities of products. Capping machines can cap hundreds of containers per minute, ensuring that your products are sealed quickly and efficiently. This increased speed allows for higher production rates and faster turnaround times, ultimately leading to more satisfied customers and increased profits.

In addition to saving time, capping machines also help save money in packaging operations. By automating the capping process, companies can reduce the need for manual labor, leading to lower labor costs and increased efficiency. Capping machines also eliminate human error, ensuring that each container is sealed correctly every time. This can help reduce the amount of product waste and minimize the risk of costly rework or recalls.

Furthermore, capping machines are versatile and can be customized to fit a wide range of packaging needs. Whether you're packaging food and beverages, pharmaceuticals, cosmetics, or household products, there is a capping machine available to suit your specific requirements. These machines are also easy to operate and maintain, making them a cost-effective long-term investment for your packaging operation.

In conclusion, capping machines offer a multitude of benefits for packaging operations, including saving time and money. By increasing the speed and accuracy of the capping process, companies can improve their productivity, reduce labor costs, and minimize product waste. With their versatility and customizability, capping machines are an essential tool for companies looking to optimize their packaging processes and stay ahead of the competition. If you're looking to streamline your packaging operations and increase efficiency, investing in a capping machine is a smart choice that will yield long-term benefits for your business.

Conclusion

In conclusion, investing in a capping machine for your packaging needs can provide numerous benefits for your business. From increased efficiency and productivity to improved product quality and consistency, the advantages of using a capping machine are clear. With 11 years of experience in the industry, our company understands the importance of staying ahead of the competition and embracing innovative technology. By incorporating a capping machine into your packaging process, you can streamline your operations, reduce costs, and ultimately, enhance your bottom line. So why wait? Upgrade your packaging system today and experience the top benefits of using a capping machine for your business.