The Benefits Of Investing In A High-Quality Linear Capping Machine

Are you looking to improve the efficiency and quality of your packaging process? Investing in a high-quality linear capping machine could be the key to streamlining production, reducing errors, and ultimately increasing your bottom line. In this article, we explore the numerous benefits of incorporating a top-of-the-line capping machine into your operation and how it can revolutionize your packaging process. Whether you're in the food and beverage industry, pharmaceuticals, or any other sector that requires precise sealing, this investment could be a game-changer for your business.

- Understanding the Importance of Capping Machines in the Packaging Industry

In the fast-paced world of the packaging industry, efficiency and consistency are key factors in ensuring the success of a business. One essential piece of equipment that plays a crucial role in achieving these goals is the linear capping machine. In this article, we will delve into the importance of capping machines in the packaging industry, specifically focusing on the benefits of investing in a high-quality linear capping machine.

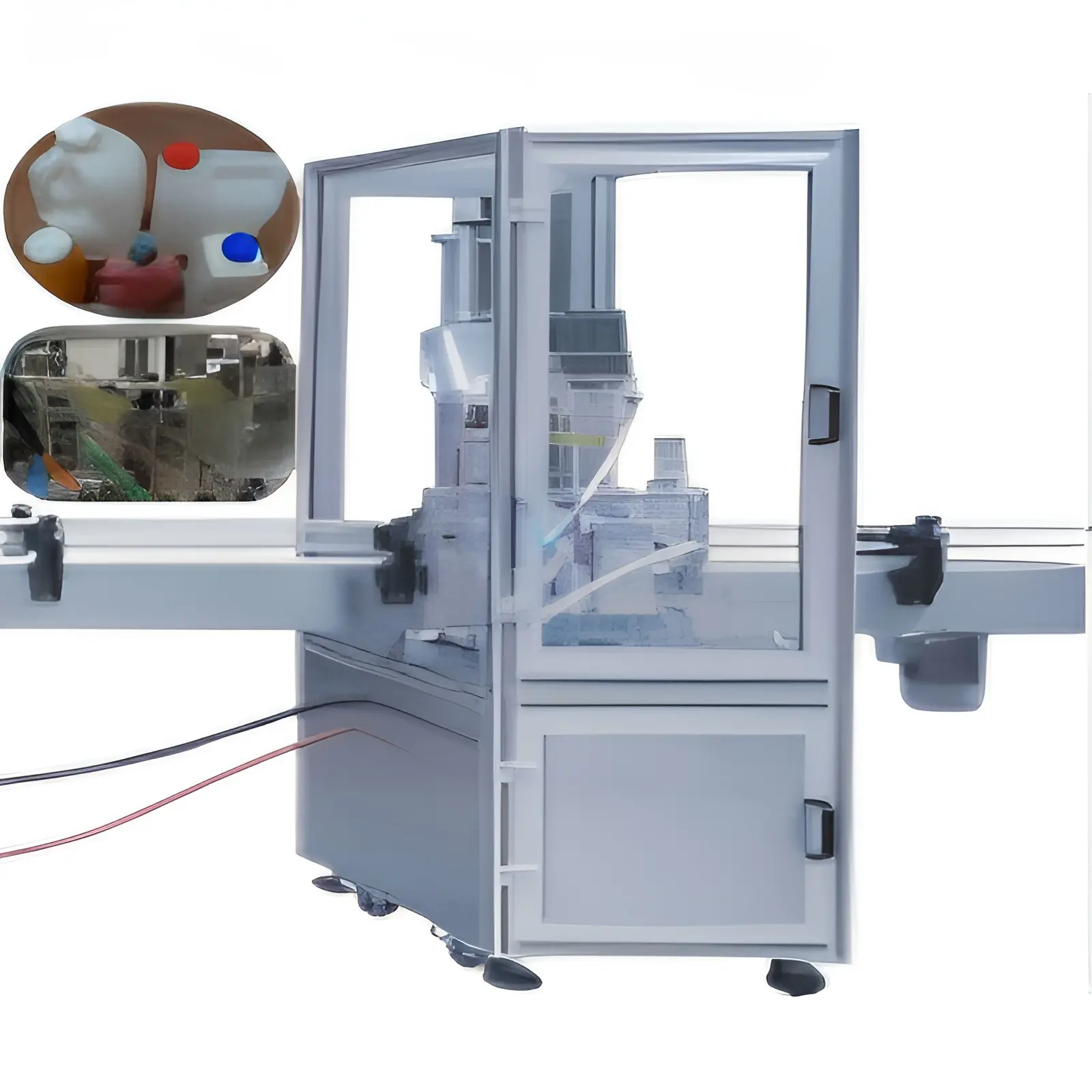

First and foremost, let's discuss what a linear capping machine actually is. A linear capping machine is a type of packaging equipment that is used to cap containers such as bottles, jars, and tubes. Unlike traditional capping machines, which typically require manual labor to operate, linear capping machines are fully automated, making them incredibly efficient and reliable. These machines use linear motion to accurately place and tighten caps onto containers, ensuring a secure seal every time.

One of the key benefits of investing in a high-quality linear capping machine is the improved efficiency it brings to your packaging process. With a linear capping machine, you can significantly increase the speed at which you cap containers, allowing you to meet high production demands without sacrificing quality. This increased efficiency not only saves you time and money but also enhances the overall productivity of your packaging operations.

Furthermore, a high-quality linear capping machine can also help improve the consistency and accuracy of your packaging process. These machines are equipped with advanced technology that allows them to precisely place and tighten caps onto containers with minimal error. This level of consistency is crucial in ensuring that each product is packaged correctly and securely, reducing the risk of leaks or spills that can lead to costly product recalls.

Another important benefit of investing in a high-quality linear capping machine is the reduction of waste and product loss. By automating the capping process, you can minimize the risk of human error and ensure that each container is properly sealed, reducing the likelihood of product spoilage or contamination. This not only helps to maintain the quality of your products but also saves you money in the long run by reducing the amount of product that goes to waste.

In conclusion, the importance of capping machines in the packaging industry cannot be overstated. Investing in a high-quality linear capping machine can provide numerous benefits to your business, including improved efficiency, consistency, and product quality. By choosing the right capping machine for your packaging operations, you can streamline your production process, reduce waste, and ultimately enhance the overall success of your business.

- High-Quality Linear Capping Machines: An Overview of Key Features

A high-quality linear capping machine is a crucial investment for manufacturers in various industries, as it plays a significant role in ensuring the efficiency and consistency of their packaging processes. In this article, we will explore the key features of high-quality linear capping machines and the benefits that come with investing in them.

One of the main features of a high-quality linear capping machine is its precision and accuracy. These machines are designed to cap containers with the utmost precision, ensuring that each cap is placed securely and tightly on the container. This level of accuracy is essential for maintaining product quality and preventing leaks or spills during transportation and storage.

Another key feature of high-quality linear capping machines is their speed and efficiency. These machines are able to cap a large number of containers in a short amount of time, increasing production output and reducing bottlenecks in the packaging line. With faster capping speeds, manufacturers can meet tight production deadlines and fulfill customer orders promptly.

Additionally, high-quality linear capping machines are equipped with advanced technology that allows for easy customization and adjustment. Manufacturers can easily change the machine settings to accommodate different container sizes and cap types, making it versatile and adaptable to various packaging requirements. This flexibility is crucial for manufacturers who produce a wide range of products with different packaging needs.

Furthermore, high-quality linear capping machines are designed for durability and long-lasting performance. These machines are built with high-quality materials and components that can withstand continuous use in a demanding production environment. By investing in a durable capping machine, manufacturers can reduce maintenance costs and downtime, ultimately increasing the overall efficiency of their packaging operation.

In conclusion, investing in a high-quality linear capping machine offers numerous benefits for manufacturers, including precision, speed, flexibility, and durability. These machines are essential for ensuring the efficiency and consistency of the packaging process, ultimately leading to higher product quality and customer satisfaction. With the advanced features and capabilities of high-quality linear capping machines, manufacturers can streamline their production processes and stay ahead of the competition.

- Advantages of Investing in a Reliable Linear Capping Machine for Your Business

When it comes to improving efficiency and productivity in your business, investing in a reliable linear capping machine can be a game-changer. These machines offer a wide range of advantages that can help streamline your production process and boost your bottom line. In this article, we will explore the benefits of investing in a high-quality linear capping machine for your business.

First and foremost, a linear capping machine can significantly increase the speed and accuracy of the capping process. These machines are designed to cap bottles or containers with precision and consistency, ensuring that each product is sealed properly. This not only saves time but also reduces the risk of product spoilage or leakage, ultimately improving the overall quality of your finished products.

In addition to speed and accuracy, linear capping machines also offer versatility and flexibility. These machines can be customized to fit a wide range of bottle sizes and shapes, making them suitable for various types of products. Whether you are packaging liquids, powders, or creams, a linear capping machine can handle the job with ease. This versatility is especially valuable for businesses that produce a diverse range of products and need a capping solution that can adapt to their changing needs.

Another key advantage of investing in a linear capping machine is the cost savings it can provide in the long run. By automating the capping process, you can reduce the need for manual labor and minimize the risk of human error. This not only increases efficiency but also reduces waste, leading to lower production costs and higher profit margins. Additionally, the durability and reliability of these machines mean that they require minimal maintenance, further reducing operating expenses over time.

Moreover, investing in a high-quality linear capping machine can also enhance the overall safety and hygiene of your production facility. These machines are built to meet strict industry standards and regulations, ensuring that your products are sealed in a clean and sterile environment. This is particularly important for businesses that operate in the food and beverage or pharmaceutical industries, where product contamination can have serious consequences.

Furthermore, with advancements in technology, modern linear capping machines are equipped with advanced features such as automatic bottle feeding, capping torque adjustment, and rejection systems for faulty products. These features not only improve efficiency but also ensure consistent quality control throughout the production process. Additionally, many of these machines are user-friendly and easy to operate, allowing your staff to quickly learn how to use them effectively.

In conclusion, investing in a reliable linear capping machine for your business offers a multitude of benefits that can ultimately improve your productivity, efficiency, and bottom line. From increased speed and accuracy to cost savings and enhanced safety, these machines are a valuable asset for any business looking to optimize their production process. With the right machine tailored to your specific needs and requirements, you can take your business to the next level and stay ahead of the competition.

- How a High-Quality Capping Machine Can Improve Efficiency and Productivity

In today's fast-paced manufacturing industry, businesses are constantly seeking ways to enhance efficiency and productivity. One often overlooked aspect of production is the capping process, which plays a vital role in ensuring the quality and integrity of the final product. Investing in a high-quality linear capping machine can make a significant impact on a company's operations, leading to improved efficiency and productivity.

A linear capping machine is a type of machinery designed to securely seal containers with caps or lids, typically used in industries such as pharmaceuticals, cosmetics, food and beverage, and household products. These machines are known for their precision and speed, offering a reliable solution for companies looking to streamline their capping process.

One of the main benefits of investing in a high-quality linear capping machine is the efficiency it brings to the production line. These machines are specifically designed to handle high volumes of containers in a short amount of time, reducing the need for manual labor and minimizing the risk of errors. This means that companies can increase their output without compromising on quality, ultimately leading to a more efficient and streamlined production process.

Furthermore, a high-quality linear capping machine can also improve productivity by reducing downtime and increasing overall throughput. These machines are built to be robust and reliable, ensuring consistent performance even under heavy usage. With faster capping speeds and fewer maintenance issues, companies can maximize their production capacity and meet customer demands more effectively.

In addition to efficiency and productivity gains, investing in a high-quality linear capping machine can also result in cost savings for businesses. By automating the capping process, companies can reduce the need for manual labor and minimize the risk of product wastage or rework. This can lead to lower production costs and higher profit margins in the long run, making it a worthwhile investment for any company looking to improve their bottom line.

Overall, the benefits of investing in a high-quality linear capping machine are clear. From improved efficiency and productivity to cost savings and enhanced quality control, these machines offer a range of advantages for businesses in various industries. By making the switch to automated capping technology, companies can stay competitive in the market and ensure the success of their operations in the long term.

- Factors to Consider When Choosing the Right Linear Capping Machine for Your Packaging Needs

When it comes to packaging products, choosing the right capping machine is essential to ensure efficiency and quality. Linear capping machines are a popular choice for many industries due to their ability to securely seal containers and bottles. In this article, we will explore the factors to consider when selecting the right linear capping machine for your packaging needs.

One of the main benefits of investing in a high-quality linear capping machine is its versatility. These machines are capable of capping a wide range of container sizes and shapes, making them ideal for businesses with diverse packaging requirements. Additionally, linear capping machines are known for their speed and precision, ensuring that your products are efficiently sealed and ready for distribution.

When choosing a linear capping machine, it is important to consider the cap size and type that your products require. Some machines are designed to handle specific cap sizes, so it is essential to select a machine that is compatible with the caps you will be using. Additionally, consider the type of caps your products require, such as screw caps, snap-on caps, or push-on caps, and ensure that the machine you choose can accommodate these types effectively.

Another important factor to consider when selecting a linear capping machine is the level of automation you require. Some machines are fully automated, while others may require manual adjustment and operation. Depending on the volume of products you are packaging and your desired level of efficiency, you may opt for a fully automated machine that can cap multiple containers simultaneously. However, if you have lower production volumes or require more flexibility in your capping process, a semi-automatic machine may be a better choice.

Additionally, consider the footprint and space requirements of the linear capping machine. Some machines are compact and easy to integrate into existing packaging lines, while others may require more space and customization. Ensure that the machine you choose fits comfortably within your production facility and can be easily integrated into your packaging process.

It is also important to consider the maintenance and support options available for the linear capping machine. Look for a manufacturer that offers reliable customer support and maintenance services to ensure that your machine operates smoothly and efficiently. Regular maintenance and servicing are essential to prolonging the lifespan of your machine and preventing costly downtime.

In conclusion, investing in a high-quality linear capping machine can bring numerous benefits to your packaging process. By considering factors such as cap size, type, automation level, footprint, and maintenance options, you can select a machine that meets your specific packaging needs and enhances the efficiency of your production line. Choose a reliable manufacturer and invest in a machine that will streamline your capping process and ensure the quality and integrity of your products.

Conclusion

In conclusion, investing in a high-quality linear capping machine has proven to be a wise decision for companies looking to improve their production efficiency and overall product quality. With 11 years of experience in the industry, we have witnessed firsthand the numerous benefits that come with incorporating a top-of-the-line capping machine into our operations. From increased speed and precision to reduced downtime and waste, the advantages are clear. By making this investment, companies can streamline their capping process and ultimately enhance their bottom line. So, don't hesitate to upgrade to a high-quality linear capping machine- your business will thank you for it.