The Ultimate Guide To Choosing The Best Pet Bottle Capping Machine

Are you in the market for a new pet bottle capping machine but unsure where to start? Look no further! In this comprehensive guide, we will walk you through everything you need to know to choose the best pet bottle capping machine for your needs. From key features to consider to tips on finding the perfect machine for your budget, this guide has got you covered. Say goodbye to tedious capping processes and hello to smooth, efficient bottling with the help of our ultimate guide.

- Understanding the Importance of Pet Bottle Capping Machines

Pet bottle capping machines play a crucial role in the packaging industry, particularly in the beverage and pharmaceutical sectors. These machines are designed to securely seal bottles with caps, ensuring the contents remain fresh and uncontaminated. As such, understanding the importance of pet bottle capping machines is essential for businesses looking to maintain product quality, improve efficiency, and enhance customer satisfaction.

One of the key benefits of using pet bottle capping machines is their ability to ensure consistent and reliable sealing of bottles. Manual capping can be prone to human error, leading to inconsistent seal quality and potential leakage. In contrast, automated capping machines can precisely apply the correct amount of torque to each cap, resulting in a tight and secure seal every time. This not only helps to maintain product freshness and extend shelf life but also minimizes the risk of spills and contamination.

In addition to ensuring quality and consistency, pet bottle capping machines also help to improve production efficiency. With their high-speed capabilities and precise operation, these machines can cap a large number of bottles in a short amount of time, significantly reducing manual labor and increasing overall output. This is especially beneficial for businesses with high production volumes, as it allows them to meet demand more effectively and streamline their production process.

Furthermore, pet bottle capping machines can also contribute to cost savings in the long run. By automating the capping process, businesses can reduce the need for manual labor, minimize the risk of errors and rework, and improve overall efficiency. This not only helps to lower production costs but also enhances productivity and profitability. Additionally, the durability and reliability of pet bottle capping machines ensure a long service life, further enhancing their cost-effectiveness.

When choosing the best pet bottle capping machine for your business, there are several factors to consider. These include the type of caps and bottles you will be using, the production volume and speed requirements, and any specific features or capabilities you may need. It is important to select a machine that is compatible with your existing production line, easy to operate and maintain, and capable of meeting your production needs.

In conclusion, pet bottle capping machines are essential tools for businesses in the packaging industry. By understanding their importance and choosing the right machine for your specific needs, you can improve product quality, enhance efficiency, and ultimately achieve greater success in the market. Whether you are a small start-up or a large-scale manufacturer, investing in a high-quality pet bottle capping machine is a decision that can benefit your business in the long term.

- Factors to Consider When Choosing a Pet Bottle Capping Machine

When it comes to choosing a pet bottle capping machine, there are several factors that need to be taken into consideration in order to select the best option for your specific needs. This ultimate guide will help you navigate through the various factors that should be considered when choosing a pet bottle capping machine.

One of the first factors to consider is the speed of the machine. Different pet bottle capping machines have different speeds, so it is important to choose one that can cap bottles at the rate that you require for your production line. Consider the volume of bottles that you will need to cap each day and choose a machine that can keep up with your production needs.

Another important factor to consider is the type of capping mechanism that the machine uses. There are various types of capping mechanisms, including screw capping, press capping, and snap capping. Each type of capping mechanism has its own advantages and disadvantages, so it is important to choose a machine that uses the type of capping mechanism that is best suited for your specific needs.

In addition to the speed and type of capping mechanism, it is also important to consider the size and shape of the bottles that you will be capping. Make sure that the pet bottle capping machine that you choose is compatible with the size and shape of the bottles that you will be using. Some machines are designed to cap only certain sizes or shapes of bottles, so it is important to choose a machine that can accommodate the bottles that you will be using.

Furthermore, consider the level of automation that you require in a pet bottle capping machine. Some machines are fully automated, while others require manual intervention. Decide how much automation you need based on the size of your production line and the level of efficiency that you are looking to achieve.

Lastly, consider the cost of the pet bottle capping machine. Prices can vary widely depending on the brand, model, and features of the machine. It is important to set a budget and choose a machine that fits within your budget while still meeting all of your needs.

In conclusion, choosing the best pet bottle capping machine requires careful consideration of factors such as speed, capping mechanism, bottle size and shape compatibility, level of automation, and cost. By taking all of these factors into account, you can select the perfect pet bottle capping machine for your production needs.

- Different Types of Pet Bottle Capping Machines Available

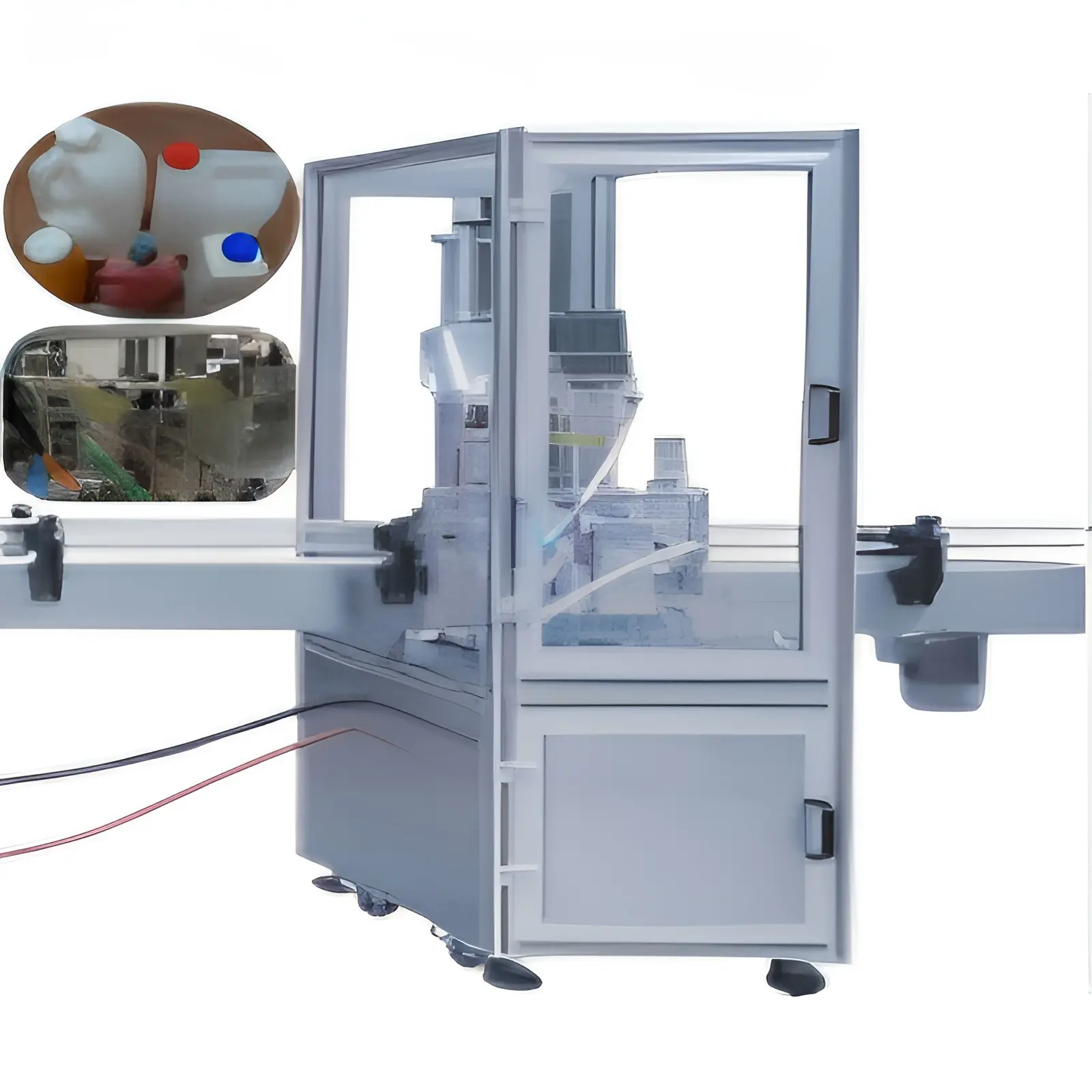

When it comes to choosing the best pet bottle capping machine, there are several different types available on the market to meet the unique needs of various industries. From manual capping machines to fully automated systems, each type offers different features and benefits that cater to different production requirements. In this ultimate guide, we will explore the various types of pet bottle capping machines available and help you choose the best one for your specific needs.

The first type of pet bottle capping machine is the manual capping machine. These machines require operators to place caps on the bottles and then manually secure them in place. While they may be more labor-intensive than automated systems, manual capping machines are an affordable option for small-scale businesses or startups. They are also ideal for products that require a delicate touch during the capping process.

Next, we have semi-automatic capping machines, which provide a middle ground between manual and fully automated systems. These machines require some manual labor, such as placing caps on bottles, but the capping process is partially automated. Semi-automatic capping machines are a popular choice for businesses that have moderate production volumes and want to increase efficiency without investing in a fully automated system.

Fully automatic capping machines are the most advanced type of pet bottle capping machine available. These machines can cap hundreds or even thousands of bottles per hour with minimal human intervention. Fully automated capping machines are ideal for high-volume production lines where speed and precision are crucial. They can be integrated seamlessly into existing production lines to streamline the capping process and maximize efficiency.

In addition to manual, semi-automatic, and fully automatic capping machines, there are also specialized capping machines designed for specific types of caps or bottles. For example, there are machines that are specifically designed for screw caps, snap caps, or trigger sprayers. These specialized machines are tailored to meet the unique requirements of different industries and ensure a perfect seal every time.

When choosing the best pet bottle capping machine for your business, it is essential to consider factors such as production volume, cap type, and budget. It is also crucial to research different manufacturers and suppliers to find a reliable and reputable machine that meets your specific needs. By understanding the different types of pet bottle capping machines available, you can make an informed decision and invest in a machine that will enhance your production process and help you achieve your business goals.

- Selecting the Right Size and Capacity for Your Production Needs

When it comes to packaging products in the food and beverage industry, one of the most crucial steps is ensuring that the bottles are securely capped. This is where a pet bottle capping machine comes in handy. However, selecting the right size and capacity for your production needs can be a daunting task. In this ultimate guide, we will explore everything you need to know about choosing the best pet bottle capping machine.

First and foremost, it is important to understand the different types of pet bottle capping machines available in the market. There are semi-automatic machines that require some manual intervention, as well as fully automatic machines that can cap hundreds of bottles per minute without any human assistance. The size and capacity of the machine will largely depend on the volume of bottles that need to be capped on a daily basis.

When selecting the right size for your production needs, it is important to consider factors such as the number of bottles to be capped per minute, the size and shape of the bottles, as well as the type of caps that need to be sealed. For small to medium-sized production lines, a semi-automatic pet bottle capping machine may be sufficient. These machines are compact, easy to operate, and can cap up to 30 bottles per minute.

For larger production lines with high-volume output, a fully automatic pet bottle capping machine is the way to go. These machines are equipped with advanced technology such as automatic cap feeding and sorting systems, as well as precision capping mechanisms to ensure a tight seal on every bottle. Fully automatic machines can cap anywhere from 60 to 300 bottles per minute, depending on the model and configuration.

In addition to size and capacity, it is also important to consider the compatibility of the pet bottle capping machine with your existing production line. Some machines are designed to work with specific bottle sizes or cap types, so be sure to check the specifications and requirements of the machine before making a purchase. It is also advisable to test the machine with a sample of your bottles and caps to ensure proper functionality and performance.

Furthermore, maintenance and support services should also be taken into account when choosing a pet bottle capping machine. Look for a reputable manufacturer that offers comprehensive warranty coverage, as well as technical support and spare parts availability. Regular maintenance and servicing will help prolong the lifespan of the machine and ensure uninterrupted production flow.

In conclusion, selecting the right size and capacity for your production needs is crucial when choosing the best pet bottle capping machine. Consider factors such as the volume of bottles to be capped, the type of caps and bottles, as well as compatibility with your existing production line. With the right machine in place, you can streamline your packaging process, improve efficiency, and deliver high-quality products to your customers.

- Top Tips for Maintenance and Troubleshooting of Pet Bottle Capping Machines

Pet bottle capping machines are essential equipment for any business that deals with packaging liquids in PET bottles. These machines are responsible for securely sealing the bottles with caps, ensuring the product inside stays fresh and free from contamination. Selecting the best pet bottle capping machine for your needs is crucial to the efficiency and effectiveness of your production line. In this comprehensive guide, we will discuss the top tips for maintaining and troubleshooting pet bottle capping machines.

Maintenance of pet bottle capping machines is a key factor in ensuring they function properly and produce consistent results. Regular maintenance not only prolongs the lifespan of the machine but also helps to prevent costly breakdowns. Some maintenance tips for pet bottle capping machines include regularly cleaning and sanitizing the machine, checking and replacing worn or damaged parts, lubricating moving parts, and calibrating the machine to ensure accurate cap placement.

Troubleshooting pet bottle capping machines can be challenging, especially when facing unexpected issues that disrupt production. One common issue is misalignment, which can result in crooked caps or caps that do not seal properly. To troubleshoot misalignment, check the alignment of the capping head and adjust it if necessary. Another common issue is cap jams, which can occur due to debris or worn parts. Clearing the jammed caps and replacing any damaged parts can help resolve this issue.

Another important aspect of maintaining and troubleshooting pet bottle capping machines is understanding the different types of capping methods and their specific requirements. There are various capping methods, including screw capping, snap capping, and press-on capping, each requiring different techniques and settings. Familiarizing yourself with the capping method used by your machine and adjusting settings accordingly can help optimize performance and prevent issues.

In addition to regular maintenance and troubleshooting, it is essential to invest in quality pet bottle capping machines from reputable manufacturers. Quality machines are more likely to operate smoothly and reliably, reducing the need for frequent maintenance and troubleshooting. When choosing a pet bottle capping machine, consider factors such as production capacity, capping speed, capping method, and compatibility with your bottle sizes and caps.

In conclusion, maintaining and troubleshooting pet bottle capping machines is essential for ensuring smooth and efficient packaging operations. By following the top tips outlined in this guide, businesses can prolong the lifespan of their machines, prevent costly breakdowns, and optimize production quality. Investing in quality machines and understanding the specific requirements of your capping method are key factors in choosing the best pet bottle capping machine for your needs.

Conclusion

In conclusion, after 11 years of experience in the industry, we have provided you with the ultimate guide to choosing the best pet bottle capping machine. By following the tips and considerations outlined in this article, you can make an informed decision and select a machine that meets your specific needs and requirements. Remember to prioritize factors such as production capacity, design flexibility, and ease of use when making your selection. Investing in the right pet bottle capping machine will not only streamline your production process but also ensure the quality and efficiency of your products. Thank you for trusting us as your go-to resource for all your packaging needs.