Comparing Bottle Capping Machine Prices: How To Choose The Right One For Your Business

Are you looking to invest in a bottle capping machine for your business, but unsure where to start? In this comprehensive guide, we explore the various factors to consider when comparing bottle capping machine prices. From production efficiency to cost-effectiveness, we break down everything you need to know to choose the right machine for your specific business needs. Keep reading to make an informed decision that will enhance your bottling operations and set your business up for success.

Factors to Consider When Comparing Bottle Capping Machine Prices

Choosing the right bottle capping machine for your business can be a crucial decision that can impact the efficiency and productivity of your operations. When comparing bottle capping machine prices, there are several factors to consider to ensure you are selecting the best option for your specific needs.

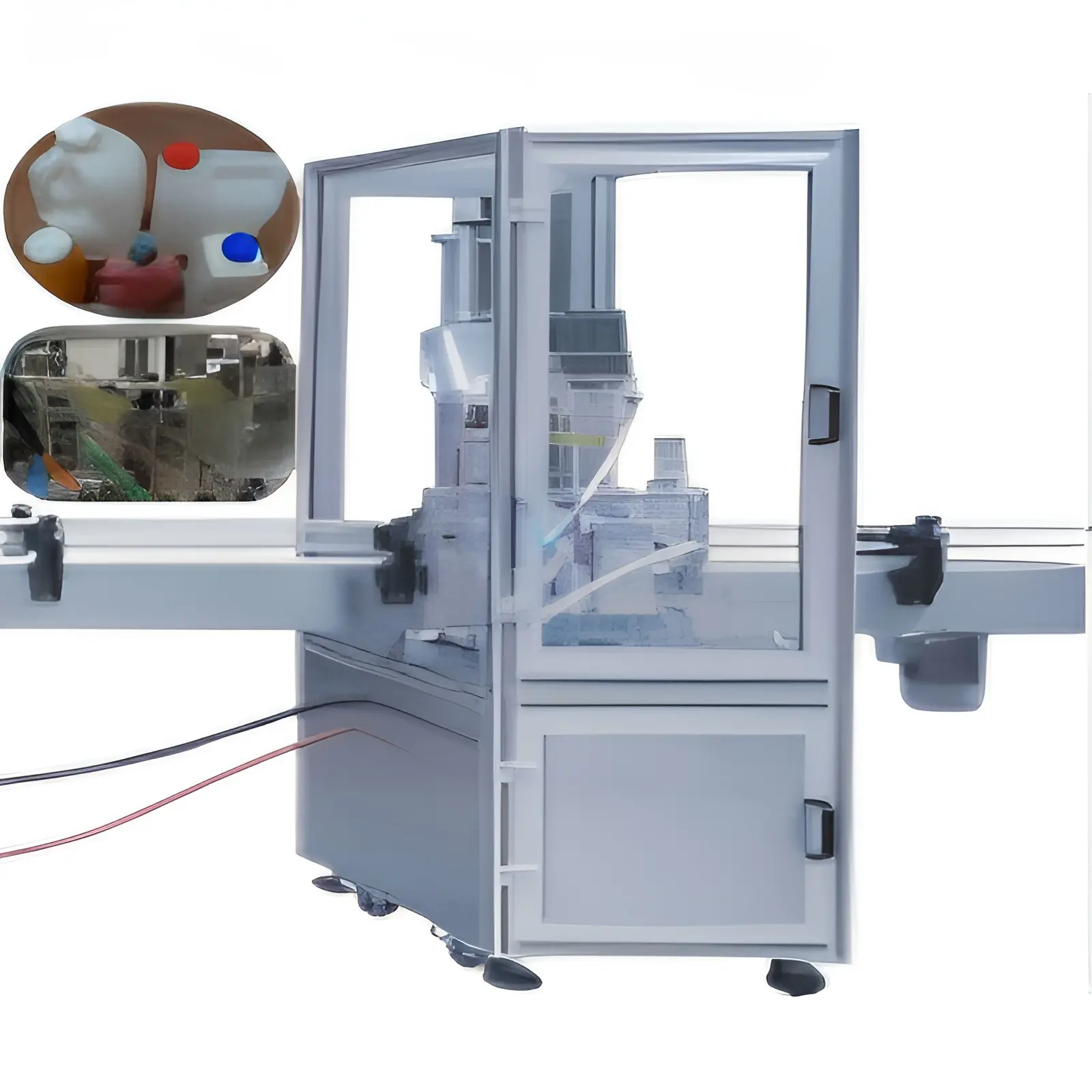

One of the first factors to consider when comparing bottle capping machine prices is the type of capping technology used. There are various types of capping machines available, including spindle cappers, chuck cappers, and snap cappers, each of which is suitable for different types of caps and bottle sizes. It is important to determine which type of capping technology is best suited for your production requirements to ensure you are investing in a machine that meets your needs.

In addition to the type of capping technology, the speed and capacity of the bottle capping machine should also be taken into consideration when comparing prices. The speed of a capping machine is measured in units per minute, with higher speeds typically resulting in higher prices. It is important to determine the production rate you require to meet your business demands and choose a capping machine with an appropriate speed capacity to ensure optimal productivity.

Another important factor to consider when comparing bottle capping machine prices is the level of automation and customization options available. Fully automated capping machines can streamline production processes and reduce labor costs, but may come at a higher price. On the other hand, semi-automated or manual capping machines may be more affordable but require more manual labor. It is important to assess your production requirements and budget constraints to determine the level of automation that is best suited for your business.

Additionally, the quality and durability of the bottle capping machine should also be taken into consideration when comparing prices. Investing in a high-quality capping machine can help prevent downtime and maintenance costs in the long run, resulting in higher efficiency and productivity. It is important to research the reputation of the manufacturer and read customer reviews to ensure you are investing in a reliable and durable machine that will last for years to come.

When comparing bottle capping machine prices, it is also important to consider the overall cost of ownership, including maintenance, training, and support services. Some manufacturers may offer warranty and maintenance packages that can help reduce operating costs and minimize downtime. It is important to factor in these costs when comparing prices to ensure you are making a cost-effective investment for your business.

In conclusion, when comparing bottle capping machine prices, it is important to consider the type of capping technology, speed and capacity, level of automation, quality and durability, and overall cost of ownership. By carefully evaluating these factors, you can choose the right bottle capping machine for your business that meets your production requirements and budget constraints.

Different Types of Bottle Capping Machines Available

When it comes to choosing the right bottle capping machine for your business, there are several factors to consider, one of the most important being the price. Bottle capping machines come in a variety of types, each with its own set of features and price points. In this article, we will explore the different types of bottle capping machines available and how to choose the right one for your business based on price.

One of the most common types of bottle capping machines is the handheld capping machine. These machines are typically more affordable than other types of capping machines and are ideal for small businesses or those with limited space. Handheld capping machines are easy to use and can cap bottles quickly and efficiently. However, they may not be suitable for high-volume production due to their manual operation.

Another type of bottle capping machine is the semi-automatic capping machine. These machines are more advanced than handheld capping machines and are capable of capping a larger number of bottles per minute. Semi-automatic capping machines are a good option for businesses with medium to high production volumes. While they may be more expensive than handheld capping machines, they offer increased efficiency and productivity.

For businesses with high production volumes, fully automatic capping machines are the best option. These machines are the most expensive of the three types but provide the highest level of automation and efficiency. Fully automatic capping machines can cap hundreds of bottles per minute, making them ideal for large-scale production operations. While the initial cost may be higher, the long-term benefits of increased productivity and reduced labor costs make fully automatic capping machines a worthwhile investment for many businesses.

When comparing bottle capping machine prices, it is important to consider not only the initial cost of the machine but also factors such as maintenance and operating costs. Some machines may require more frequent maintenance or replacement parts, which can add to the overall cost of ownership. It is also important to consider the level of customer support and service provided by the manufacturer, as this can impact the overall value of the machine.

In conclusion, choosing the right bottle capping machine for your business is a decision that should not be taken lightly. By considering factors such as price, production volume, and maintenance costs, you can ensure that you choose a machine that meets your business needs and budget. Whether you opt for a handheld, semi-automatic, or fully automatic capping machine, investing in the right equipment can help streamline your production process and increase efficiency in the long run.

Determining Your Business Needs and Requirements

When it comes to choosing the right bottle capping machine for your business, one of the most crucial factors to consider is the price. Determining your business needs and requirements is essential in order to make an informed decision that will ultimately benefit your bottom line.

There are several key factors to take into account when comparing bottle capping machine prices. Firstly, it is important to consider the size and scale of your business operations. Are you a small start-up looking to ramp up production, or a larger company in need of a high-speed capping solution? Understanding the specific needs of your business will help you narrow down your options and choose a machine that is perfectly suited to your requirements.

Another important aspect to consider is the type of bottles you will be capping. Different machines are designed to handle different types of bottles, from standard glass bottles to plastic containers and even specialty shapes. It is important to choose a machine that is compatible with the specific bottles you will be using in order to ensure smooth and efficient operation.

In addition to bottle type, it is also important to consider the level of automation you require. Some bottle capping machines are fully automated, while others require manual intervention. Automated machines are generally more expensive, but can significantly increase production efficiency and reduce labor costs in the long run. On the other hand, manual machines are more affordable and may be suitable for smaller businesses with lower production volumes.

When comparing bottle capping machine prices, it is also important to consider the level of customization and flexibility you require. Some machines come with a range of customization options, allowing you to adjust settings and parameters to suit your specific needs. Others may be more basic and less easily adaptable. Depending on the complexity of your capping requirements, you may need a machine that offers greater flexibility and customization capabilities.

Lastly, it is important to consider the overall quality and reliability of the machine. While price is certainly an important factor, it is also essential to choose a machine that is built to last and able to withstand the rigors of daily use. Look for machines from reputable manufacturers with a track record of producing high-quality, reliable equipment.

In conclusion, determining your business needs and requirements is essential when comparing bottle capping machine prices. By considering factors such as the size and scale of your operations, the type of bottles you will be capping, the level of automation you require, and the level of customization and reliability you need, you can make an informed decision that will benefit your business in the long run. Remember to choose a machine that is not only affordable, but also capable of meeting your specific capping requirements and delivering consistent, high-quality results.

Evaluating Quality and Performance of Bottle Capping Machines

When it comes to choosing a bottle capping machine for your business, there are a variety of factors to consider. One of the most important aspects to evaluate before making a purchase is the quality and performance of the machine. In this article, we will delve into the key points to keep in mind when comparing bottle capping machine prices to ensure you choose the right one for your specific needs.

Quality is paramount when it comes to bottle capping machines. A high-quality machine will not only be more efficient and reliable, but it will also have a longer lifespan, ultimately saving you money in the long run. When evaluating the quality of a bottle capping machine, consider the materials it is made of, the reputation of the manufacturer, and any reviews or testimonials from other users.

Performance is another crucial factor to consider when comparing bottle capping machine prices. A machine that can cap bottles quickly and accurately will increase productivity and reduce downtime, ultimately leading to higher profits for your business. Look for machines that offer a range of speed and torque settings to accommodate different bottle sizes and materials.

In addition to quality and performance, cost is a key consideration when choosing a bottle capping machine. Prices can vary widely depending on factors such as the machine's capacity, features, and brand. It's important to set a budget and stick to it, but also be willing to invest in a high-quality machine that will meet your business's needs in the long term.

To ensure you are getting the best value for your money, it's important to compare prices from multiple sources. Look for reputable suppliers that offer competitive pricing and consider factors such as warranties, maintenance costs, and customer support. Don't be afraid to negotiate with suppliers to get the best deal possible.

Ultimately, choosing the right bottle capping machine for your business is a decision that should not be taken lightly. By carefully evaluating the quality and performance of the machines you are considering, as well as comparing prices from various sources, you can make an informed decision that will benefit your business for years to come.

In conclusion, when comparing bottle capping machine prices, it's important to consider factors such as quality, performance, and cost to ensure you choose the right machine for your business. By taking the time to research and evaluate your options, you can make a smart investment that will help your business thrive.

Budget and Long-Term Cost Considerations

When it comes to choosing the right bottle capping machine for your business, there are a variety of factors to consider. One of the most important considerations is the price of the machine, as this will have a significant impact on your budget and long-term cost considerations.

Before making a decision on which bottle capping machine to purchase, it is important to do thorough research on the prices of different machines. There are a wide range of bottle capping machines available on the market, each with varying prices depending on their features, capabilities, and brand reputation.

One of the first things to consider when comparing bottle capping machine prices is your budget. It is essential to determine how much you are willing to invest in a bottle capping machine, taking into account not only the initial purchase price but also any additional costs such as installation, maintenance, and training.

Once you have established your budget, it is important to research different types of bottle capping machines to determine which one best suits your business needs. Some machines may be more expensive upfront but offer additional features that can save you money in the long run, such as faster production speeds or reduced maintenance costs.

Another important factor to consider when comparing bottle capping machine prices is the long-term cost considerations. While it may be tempting to choose a cheaper machine upfront, it is crucial to consider the potential costs of maintenance, repairs, and replacement parts over time.

In addition to the initial purchase price, it is important to consider the overall cost of ownership for each bottle capping machine. This includes factors such as energy efficiency, ease of maintenance, and the availability of spare parts. Investing in a higher quality machine with lower long-term costs can save you money in the long run and ensure that your production process runs smoothly and efficiently.

When comparing bottle capping machine prices, it is also important to consider the reputation of the manufacturer. Choosing a machine from a reputable manufacturer with a history of producing high-quality, reliable products can help you avoid costly repairs and downtime in the future.

In conclusion, when choosing a bottle capping machine for your business, it is essential to consider both your budget and long-term cost considerations. By carefully researching and comparing different machines based on price, features, and manufacturer reputation, you can ensure that you invest in a machine that meets your needs and provides a solid return on investment for your business.

Conclusion

In conclusion, when it comes to choosing the right bottle capping machine for your business, it is essential to consider factors such as production volume, budget, and the specific requirements of your product packaging. By comparing prices and features of different machines, you can make an informed decision that will benefit your business in the long run. With 11 years of experience in the industry, we understand the importance of investing in quality machinery that will streamline your production process and improve efficiency. Contact us today to find the perfect bottle capping machine for your business.