The Ultimate Guide To Alcohol Bottle Filling Machines: Everything You Need To Know

Are you looking to streamline your alcohol bottling process and increase efficiency in your production line? Look no further than the comprehensive guide to alcohol bottle filling machines. In this article, we delve into everything you need to know about these essential tools, from the different types available to their key features and benefits. Whether you're a seasoned industry professional or just starting out, this ultimate guide will provide you with invaluable insights to help optimize your bottling operations.

- Understanding the Importance of Alcohol Bottle Filling Machines

Alcohol bottle filling machines have become a staple in the beverage industry, streamlining the bottling process and ensuring efficiency and accuracy. These machines play a crucial role in the production of alcoholic beverages, from wines and spirits to craft beers and ciders. Understanding the importance of alcohol bottle filling machines is essential for any business looking to maintain high quality standards and meet customer demand.

One of the key benefits of using alcohol bottle filling machines is the level of precision and consistency they provide. These machines are designed to fill bottles with the exact amount of liquid, ensuring that each product meets the same standard of quality. This not only enhances the overall product consistency but also reduces waste and improves production efficiency.

Additionally, alcohol bottle filling machines are designed to be versatile and flexible, accommodating a wide range of bottle shapes and sizes. This flexibility allows businesses to easily adapt to changing market trends and customer preferences, making it easier to introduce new products or packaging options.

Another important aspect of alcohol bottle filling machines is their ability to increase production output and reduce labor costs. These machines are capable of filling a large number of bottles in a relatively short amount of time, speeding up the production process and allowing businesses to meet higher demand without increasing labor costs. This can result in significant cost savings and improved overall efficiency.

In terms of quality control, alcohol bottle filling machines play a crucial role in ensuring that each bottle is filled accurately and consistently. This helps to prevent under or overfilling, which can impact the taste, appearance, and overall quality of the product. By using these machines, businesses can maintain a high level of quality control and ensure that every bottle meets their standards.

Overall, understanding the importance of alcohol bottle filling machines is essential for any business looking to maintain high quality standards, increase production efficiency, and reduce costs. Investing in a quality filling machine can help businesses stay competitive in the market and meet the growing demands of customers. So, if you are in the business of producing alcoholic beverages, consider the benefits of using an alcohol bottle filling machine to streamline your production process and enhance the overall quality of your products.

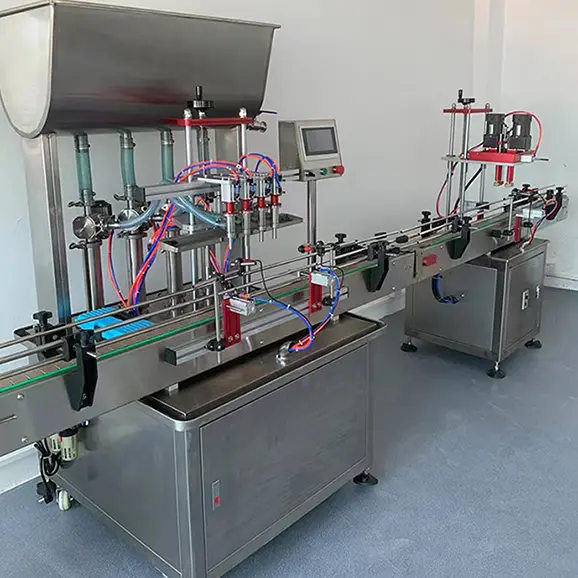

- Types of Alcohol Bottle Filling Machines Available in the Market

Alcohol bottle filling machines are essential for distilleries, breweries, and other alcohol producers to efficiently and accurately fill bottles with their products. These machines come in a variety of types, each suited to different production needs and volumes. In this ultimate guide to alcohol bottle filling machines, we will discuss the types of machines available in the market, the key features to consider when choosing one, and some top manufacturers to consider.

Types of Alcohol Bottle Filling Machines

1. Gravity Fillers: Gravity fillers are a simple and cost-effective option for small-scale producers. In this type of machine, the bottles are filled by gravity, as the liquid flows from a holding tank into the bottles. Gravity fillers are best suited for filling still or carbonated beverages.

2. Piston Fillers: Piston fillers use a piston and cylinder mechanism to accurately dispense a precise amount of liquid into each bottle. These machines are ideal for filling bottles with viscous liquids or products that require a high level of accuracy and consistency.

3. Overflow Fillers: Overflow fillers are commonly used in the alcohol industry for filling bottles with foamy liquids, such as beer or sparkling wine. In this type of machine, the liquid is pumped into the bottle until it overflows, ensuring a consistent fill level in each bottle.

4. Rotary Fillers: Rotary fillers are high-speed machines that can fill multiple bottles simultaneously. These machines are ideal for large-scale production and can handle a wide range of bottle sizes and shapes.

Key Features to Consider When Choosing an Alcohol Bottle Filling Machine

When choosing an alcohol bottle filling machine, it is important to consider the following key features:

1. Production volume: Consider the volume of bottles you need to fill per hour to choose a machine that can meet your production needs.

2. Bottle size and shape: Choose a machine that can accommodate the size and shape of your bottles to ensure a proper fill.

3. Automation level: Decide whether you need a manual, semi-automatic, or fully automatic machine based on your production requirements and budget.

4. Filling accuracy: Look for a machine that can accurately dispense the desired amount of liquid into each bottle to maintain product consistency.

Top Manufacturers of Alcohol Bottle Filling Machines

Some top manufacturers of alcohol bottle filling machines include:

1. Krones: Krones is a leading manufacturer of beverage filling and packaging equipment, including alcohol bottle filling machines.

2. GEA: GEA provides a wide range of filling solutions for the alcohol industry, from small-scale gravity fillers to high-speed rotary fillers.

3. IC Filling Systems: IC Filling Systems specializes in filling machines for the alcohol industry and offers customized solutions to meet specific production requirements.

In conclusion, choosing the right alcohol bottle filling machine is crucial for ensuring efficient and accurate production. By considering the types of machines available in the market, key features to look for, and top manufacturers to consider, alcohol producers can make an informed decision to meet their production needs.

- Key Features to Consider When Choosing a Alcohol Bottle Filling Machine

Alcohol bottle filling machines are a crucial piece of equipment for any brewery, distillery, or beverage production facility. These machines automate the process of filling bottles with alcohol, saving time and ensuring accuracy and consistency. When choosing a alcohol bottle filling machine, there are several key features to consider to ensure you select the best machine for your needs.

One important factor to consider when choosing an alcohol bottle filling machine is the type of bottles you will be filling. Different machines are designed to handle different bottle shapes and sizes, so it is important to choose a machine that is compatible with the bottles you will be using. Some machines are designed specifically for filling glass bottles, while others are better suited for plastic or aluminum bottles.

Another important feature to consider is the filling method used by the machine. There are several different types of filling methods, including gravity filling, piston filling, and vacuum filling. Each method has its own pros and cons, so it is important to choose a machine that uses a filling method that is best suited to your specific needs.

Accuracy is also a crucial factor to consider when choosing an alcohol bottle filling machine. The machine you choose should be able to fill bottles with the exact amount of alcohol required, without overfilling or underfilling. Look for a machine with a high level of accuracy to ensure that your products meet quality standards and avoid wastage.

Ease of operation and maintenance is another key feature to consider when choosing a alcohol bottle filling machine. The machine should be user-friendly and easy to operate, with clear instructions and controls that are easy to understand. It should also be easy to clean and maintain, to ensure that it continues to operate efficiently and effectively.

Finally, consider the production capacity of the machine. Choose a machine that is capable of filling the number of bottles you require in a given time frame. If your production needs are likely to increase in the future, choose a machine with a higher production capacity to accommodate this growth.

In conclusion, when choosing a alcohol bottle filling machine, consider the type of bottles you will be filling, the filling method used by the machine, the accuracy of the machine, ease of operation and maintenance, and the production capacity of the machine. By carefully considering these key features, you can select the best alcohol bottle filling machine for your specific needs and ensure that your products are filled accurately and efficiently.

- Common Issues and Troubleshooting Tips for Alcohol Bottle Filling Machines

Alcohol bottle filling machines are essential equipment for any distillery or beverage production facility. These machines are designed to efficiently and accurately fill bottles with alcohol, ensuring consistent fill levels and minimizing waste. However, like any piece of machinery, alcohol bottle filling machines can experience common issues that may disrupt production. In this guide, we will explore the most common issues that can arise with alcohol bottle filling machines and provide troubleshooting tips to help you address them effectively.

One of the most common issues with alcohol bottle filling machines is inconsistent fill levels. This can be caused by a variety of factors, including a malfunctioning pump or sensor, air bubbles in the product, or improper calibration of the machine. To troubleshoot this issue, start by checking the pump and sensor for any signs of damage or malfunction. If the pump or sensor is not functioning properly, it may need to be repaired or replaced.

Air bubbles in the product can also cause inconsistent fill levels. To prevent this issue, make sure that the product is properly degassed before filling. Additionally, check the machine's calibration to ensure that it is set to the correct fill level. If the calibration is off, adjust it accordingly to ensure consistent fills.

Another common issue with alcohol bottle filling machines is leakage during the filling process. This can be caused by worn or damaged seals, loose fittings, or improper alignment of the filling nozzles. To troubleshoot this issue, inspect the seals and fittings for any signs of wear or damage. Replace any worn or damaged components to prevent leakage.

Additionally, check the alignment of the filling nozzles to ensure that they are properly positioned over the bottles during the filling process. If the nozzles are misaligned, adjust them accordingly to prevent leakage.

In some cases, alcohol bottle filling machines may experience issues with clogging or blockages in the filling nozzles. This can be caused by debris or product buildup in the nozzles, which can impede the flow of product into the bottles. To troubleshoot this issue, carefully clean the filling nozzles to remove any debris or buildup. You can use a cleaning solution or compressed air to clear any clogs and ensure smooth operation of the machine.

Overall, alcohol bottle filling machines are essential equipment for efficiently filling bottles with alcohol. By understanding the common issues that can arise with these machines and implementing troubleshooting tips, you can ensure smooth and reliable operation of your filling equipment. By following the tips outlined in this guide, you can address common issues with alcohol bottle filling machines and keep your production running smoothly.

- Best Practices for Maintaining and Operating Alcohol Bottle Filling Machines

Alcohol bottle filling machines are essential equipment for any distillery, winery, or beverage production facility. These machines automate the process of filling bottles with alcohol, ensuring efficiency and consistency in production. To ensure the smooth operation of your alcohol bottle filling machine, it is important to follow best practices for maintenance and operation.

1. Regular Cleaning and Maintenance

One of the most important best practices for maintaining alcohol bottle filling machines is regular cleaning and maintenance. Residue from alcohol can build up in the machine over time, leading to clogs and malfunctions. It is recommended to clean the machine after each use to prevent buildup and ensure optimal performance. In addition, regular maintenance checks should be performed to identify and address any potential issues before they become major problems.

2. Calibration and Adjustment

Another key aspect of operating alcohol bottle filling machines is calibration and adjustment. The machine should be calibrated regularly to ensure accurate filling levels and prevent overfilling or underfilling of bottles. Additionally, adjustments may need to be made as different types of alcohol require different filling settings. It is important to carefully monitor the filling process and make any necessary adjustments to maintain consistency and quality.

3. Proper Training for Operators

Proper training for operators is essential for the successful operation of alcohol bottle filling machines. Operators should be trained on how to safely and effectively use the machine, as well as how to perform routine maintenance tasks. By ensuring that operators are knowledgeable and skilled in operating the machine, you can minimize the risk of accidents and maximize efficiency in production.

4. Quality Control Measures

Quality control measures are crucial for ensuring the integrity of the alcohol being filled into bottles. It is important to regularly test the alcohol for purity and consistency, as well as to conduct visual inspections of filled bottles for any defects or inconsistencies. By implementing quality control measures, you can ensure that your alcohol bottle filling machine is producing high-quality products that meet industry standards.

In conclusion, maintaining and operating alcohol bottle filling machines requires attention to detail and adherence to best practices. By following the tips outlined in this guide, you can ensure the smooth operation of your machine and produce high-quality alcohol products. Remember to prioritize regular cleaning and maintenance, calibration and adjustment, proper training for operators, and quality control measures to achieve optimal performance from your alcohol bottle filling machine.

Conclusion

In conclusion, alcohol bottle filling machines are essential in ensuring efficiency and accuracy in the production process of alcoholic beverages. Whether you are a small craft brewery or a large distillery, investing in the right filling machine can significantly improve your productivity and help you meet the demands of your customers. With our 11 years of experience in the industry, we understand the importance of choosing the right equipment for your specific needs. By following the guidelines outlined in this ultimate guide, you can make an informed decision and ensure the success of your business. Cheers to smoother production processes and higher quality products with the help of alcohol bottle filling machines!