The Ultimate Guide To Small Tube Filling Machines: Choosing The Best Option For Your Needs

Are you in the market for a small tube filling machine but overwhelmed by the variety of options available? Look no further! In this comprehensive guide, we will walk you through everything you need to know to choose the best option for your specific needs. Whether you are a newbie or an experienced professional, this article will provide you with valuable insights to make an informed decision. Let's dive into the world of small tube filling machines and find the perfect fit for your business!

- Understanding the Different Types of Small Tube Filling Machines

Small tube filling machines are essential tools for businesses in various industries, such as pharmaceuticals, cosmetics, and food production. They play a crucial role in efficiently filling tubes with creams, gels, ointments, and other products. However, with the variety of options available on the market, it can be overwhelming to choose the best machine for your specific needs. In this ultimate guide, we will delve into the different types of small tube filling machines to help you make an informed decision.

1. Manual Tube Filling Machines:

Manual tube filling machines are ideal for small-scale production or businesses with limited budgets. These machines require operators to manually fill and seal tubes, making them suitable for low-volume production. They are easy to operate and maintain, making them a cost-effective option for businesses just starting in the industry.

2. Semi-Automatic Tube Filling Machines:

Semi-automatic tube filling machines are a step up from manual machines, offering increased production efficiency and accuracy. These machines require operators to load empty tubes and fill them with the desired product, while the machine handles the sealing process. They are suitable for businesses with moderate production volumes and can handle a variety of tube sizes and materials.

3. Fully-Automatic Tube Filling Machines:

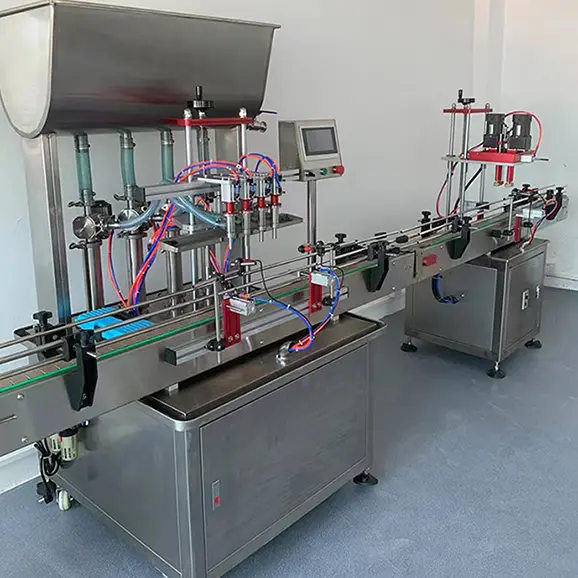

Fully-automatic tube filling machines are the most advanced option available, offering high-speed production and precision filling capabilities. These machines can handle large production volumes and are ideal for businesses with high demand for tube-filled products. They feature automatic tube loading, filling, and sealing processes, reducing the need for manual labor and increasing overall efficiency.

4. Rotary Tube Filling Machines:

Rotary tube filling machines are a specialized type of fully-automatic machine that can handle high-speed production and multiple tube filling processes simultaneously. These machines are equipped with rotary mechanisms that can fill, seal, and label tubes in a continuous process. They are suitable for businesses with high-volume production requirements and offer unparalleled efficiency and accuracy.

5. Hot Air Tube Filling Machines:

Hot air tube filling machines are specifically designed for products that require hot filling processes, such as creams, waxes, and ointments. These machines use hot air to melt the product before filling it into tubes, ensuring a consistent and uniform fill. They are ideal for businesses in the cosmetics and pharmaceutical industries that require precise temperature control during the filling process.

In conclusion, choosing the right small tube filling machine for your business is crucial for maximizing production efficiency and quality. Consider factors such as production volume, product type, and budget when selecting the best option for your needs. Whether you opt for a manual, semi-automatic, fully-automatic, rotary, or hot air tube filling machine, investing in the right equipment will help streamline your production processes and meet the demands of your customers.

- Factors to Consider When Choosing a Small Tube Filling Machine

Small tube filling machines are essential equipment for businesses in industries such as pharmaceuticals, cosmetics, food, and more that require packaging products in small tubes. With the market flooded with countless options, choosing the right small tube filling machine can be a daunting task. In this ultimate guide, we will delve into the factors that you should consider when selecting a small tube filling machine to ensure that you make the best choice for your specific needs.

1. Output Capacity:

One of the most critical factors to consider when choosing a small tube filling machine is the output capacity. The output capacity of a small tube filling machine refers to the number of tubes it can fill per minute. The output capacity you require will depend on the volume of products you need to package and the speed at which you need to do so. Be sure to select a small tube filling machine that can meet your production needs efficiently.

2. Tube Size and Material:

Another crucial factor to consider is the size and material of the tubes that the machine can fill. Small tube filling machines come in various sizes to accommodate different tube diameters and lengths. Make sure that the machine you choose can handle the size of tubes you will be using. Additionally, consider the material of the tubes, as some machines may be better suited for filling specific materials such as plastics, aluminum, or laminates.

3. Filling Accuracy:

Filling accuracy is essential to ensure that each tube is filled with the right amount of product. Look for a small tube filling machine that offers precise filling accuracy to avoid wastage and ensure consistency in the volume of product in each tube. Some machines come with advanced features such as automatic volume adjustment and sensors to maintain filling accuracy.

4. Automation Level:

The level of automation of a small tube filling machine can significantly impact your production efficiency. Fully automated machines can streamline the filling process, reduce labor costs, and minimize human error. However, they may come at a higher cost. Evaluate your production volume and budget to determine the appropriate level of automation for your needs.

5. Versatility and Flexibility:

Consider the versatility and flexibility of the small tube filling machine in handling different types of products and packaging. Some machines are designed for specific types of products, while others offer interchangeable parts or adjustable settings to accommodate various products. Choose a machine that can adapt to your changing production requirements.

In conclusion, choosing the right small tube filling machine is crucial for ensuring efficient and reliable packaging of products in small tubes. By considering factors such as output capacity, tube size and material, filling accuracy, automation level, and versatility, you can select the best option for your specific needs. Take the time to research and compare different machines to make an informed decision that will optimize your production process and meet your goals.

- Comparing the Top Small Tube Filling Machine Brands

Small tube filling machines are essential for businesses in various industries, including pharmaceuticals, cosmetics, food, and more. These machines are used to fill tubes with products such as creams, lotions, gels, and ointments. With a variety of brands on the market, it can be overwhelming to choose the best option for your needs. In this article, we will compare the top small tube filling machine brands to help you make an informed decision.

One of the leading brands in the small tube filling machine industry is ABC Machinery. Known for their high-quality machines, ABC Machinery offers a range of small tube fillers that are suitable for different production needs. Their machines are designed for efficiency and precision, ensuring that each tube is filled accurately and consistently. ABC Machinery also provides excellent customer support and after-sales service, making them a reliable choice for businesses looking for a long-term investment.

Another top brand in the small tube filling machine market is XYZ Equipment. With a reputation for innovation and reliability, XYZ Equipment offers a wide range of small tube fillers that cater to various industries. Their machines are equipped with advanced technology, such as automatic tube loading and filling, to streamline the production process. XYZ Equipment also offers customization options to meet specific requirements, making them a versatile choice for businesses with unique needs.

In addition to ABC Machinery and XYZ Equipment, DEF Industries is another reputable brand in the small tube filling machine industry. DEF Industries is known for their durable and user-friendly machines that are easy to operate and maintain. Their small tube fillers are designed to fill tubes of different sizes and shapes, making them ideal for businesses with diverse product lines. DEF Industries also offers training and technical support to help businesses optimize their production processes.

When choosing a small tube filling machine, it is important to consider factors such as production capacity, product requirements, and budget. ABC Machinery, XYZ Equipment, and DEF Industries are all top brands that offer reliable and efficient machines for businesses of all sizes. By comparing the features and benefits of these brands, you can choose the best small tube filling machine for your specific needs.

In conclusion, small tube filling machines play a crucial role in the production process for businesses in various industries. By selecting a reputable brand such as ABC Machinery, XYZ Equipment, or DEF Industries, you can ensure that your production process runs smoothly and efficiently. Consider the features and benefits of each brand to choose the best small tube filling machine for your business needs.

- Tips for Properly Maintaining Your Small Tube Filling Machine

Small tube filling machines are essential equipment for businesses in industries such as pharmaceuticals, cosmetics, and food packaging. They provide a convenient and efficient way to fill and seal small tubes with various substances. However, like any other machinery, these filling machines require proper maintenance to ensure they function optimally and have a longer lifespan. In this article, we will provide you with valuable tips for properly maintaining your small tube filling machine.

First and foremost, it is essential to regularly clean your small tube filling machine to prevent the build-up of residue and contaminants. This can be done by using a mild detergent and warm water to wash the machine's components thoroughly. Make sure to remove any leftover product from the tubes, nozzles, and other parts of the machine to prevent contamination of future products.

In addition to regular cleaning, it is crucial to lubricate the moving parts of the machine to prevent friction and wear. Using a high-quality lubricant specifically designed for small tube filling machines will help maintain the machine's efficiency and prolong its lifespan. Be sure to follow the manufacturer's recommendations for lubrication intervals and methods to ensure the machine operates smoothly.

Another important maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check for loose or damaged components, leaks, and irregularities in the filling process. Addressing these issues promptly can prevent more significant problems from occurring and ensure the machine continues to work effectively.

Calibrating your small tube filling machine regularly is also crucial for maintaining its accuracy and consistency. Over time, the machine's settings may drift, leading to inaccuracies in the filling process. By calibrating the machine according to the manufacturer's specifications, you can ensure precise filling and seal quality.

Furthermore, it is essential to train your staff properly on how to operate and maintain the small tube filling machine. Providing comprehensive training will help prevent issues caused by operator error and ensure that the machine is used correctly. Additionally, establishing a regular maintenance schedule and keeping detailed records of maintenance activities will help track the machine's performance and identify any potential issues before they escalate.

In conclusion, proper maintenance of your small tube filling machine is crucial for ensuring its optimal performance and longevity. By following the tips outlined in this article, you can keep your machine in top condition and avoid costly repairs or downtime. Remember to clean, lubricate, inspect, calibrate, and train your staff regularly to maximize the efficiency and reliability of your small tube filling machine.

- Maximizing Efficiency with Your Chosen Small Tube Filling Machine

Small tube filling machines are essential tools for businesses looking to streamline their production processes and maximize efficiency. These machines are specially designed to fill small tubes with various substances, such as creams, ointments, gels, and more. In this comprehensive guide, we will discuss everything you need to know about small tube filling machines, from choosing the best option for your needs to maximizing efficiency in your production line.

When it comes to selecting the right small tube filling machine for your business, there are several factors to consider. The first step is to determine your specific needs and requirements. Consider the type of products you will be filling into the tubes, the volume of production you need to achieve, and any special features or functionalities you require. Once you have a clear understanding of your needs, you can start researching different types of small tube filling machines available on the market.

There are several types of small tube filling machines to choose from, including manual, semi-automatic, and fully automatic machines. Manual machines are suitable for small-scale production where precision and control are crucial. Semi-automatic machines are ideal for medium-sized production lines that require a balance between speed and accuracy. Fully automatic machines are best suited for high-volume production lines where speed and efficiency are the top priorities.

In addition to the type of machine, you should also consider the filling method and technology used. Some small tube filling machines use piston filling technology, while others use peristaltic pumps or rotary technology. Each filling method has its advantages and limitations, so it's important to choose the one that best suits your needs.

Once you have selected the right small tube filling machine for your business, it's essential to focus on maximizing efficiency in your production line. One way to do this is by ensuring that your machine is properly maintained and serviced regularly. This will help prevent downtime and reduce the risk of costly breakdowns.

Another way to maximize efficiency with your small tube filling machine is by optimizing your production process. This includes streamlining your workflow, reducing waste, and improving overall productivity. By investing in quality control measures and training your staff on best practices, you can ensure that your production line runs smoothly and efficiently.

In conclusion, small tube filling machines are invaluable tools for businesses in the cosmetics, pharmaceutical, and other industries. By choosing the right machine for your needs and implementing strategies to maximize efficiency in your production line, you can achieve greater productivity and profitability. Whether you are a small business looking to scale up your production or a large corporation aiming to streamline your operations, investing in a high-quality small tube filling machine is a smart choice.

Conclusion

With 11 years of experience in the industry, we have truly become experts in the field of small tube filling machines. We have provided you with the ultimate guide to choosing the best option for your needs, offering insight into the various types of machines available and factors to consider when making your decision. By taking the time to carefully assess your requirements and compare the options, you can be confident in selecting the perfect small tube filling machine for your business. Whether you are looking for speed, accuracy, or versatility, there is a machine out there that will meet your needs. So, don't delay - invest in a quality small tube filling machine today and watch your production process become more efficient and effective than ever before. Thank you for reading our guide, and we wish you all the best in your future endeavors with small tube filling machines.