The Ultimate Guide To Choosing The Best Beer Bottle Capping Machine

Are you tired of dealing with inadequate or inefficient beer bottle capping machines? Look no further! In this comprehensive guide, we will walk you through everything you need to know to choose the best beer bottle capping machine for your needs. From factors to consider, to key features and recommendations, we’ve got you covered. Say goodbye to subpar equipment and hello to perfectly capped bottles every time. Keep reading to revolutionize your beer bottling process today!

- Understanding the Importance of a Quality Beer Bottle Capping Machine

When it comes to brewing beer, one of the most important steps in the process is capping the bottles. A quality beer bottle capping machine is essential to ensure that your beer stays fresh and carbonated for a longer period of time. In this ultimate guide, we will delve into the importance of choosing the best beer bottle capping machine for your brewing needs.

First and foremost, a reliable beer bottle capping machine is crucial for maintaining the integrity of your beer. The capping process seals the bottle, preventing oxygen from entering and causing the beer to go stale. A good capping machine will create a tight seal that keeps your beer fresh and carbonated, ensuring that it tastes as intended.

In addition to preserving the quality of your beer, a quality capping machine also helps to streamline your bottling process. With a machine that is easy to use and efficient, you can cap bottles quickly and efficiently, saving you time and allowing you to focus on other aspects of your brewing operation. This is especially important for commercial breweries that need to cap a large volume of bottles on a regular basis.

Another key factor to consider when choosing a beer bottle capping machine is the type of caps it is compatible with. There are different types of caps available, including crown caps, twist-off caps, and swing-top caps. Make sure to select a capping machine that is designed to work with the type of caps you prefer to use for your beer bottles.

When researching beer bottle capping machines, it is also important to consider the level of automation and customization that you require. Some machines offer manual operation, while others are fully automated and can cap multiple bottles at once. Think about your production needs and choose a machine that aligns with the size of your operation.

Additionally, quality and durability are important factors to keep in mind when selecting a beer bottle capping machine. Look for machines that are made from sturdy materials and have a reputation for reliability. Investing in a high-quality machine upfront can save you money and headaches down the line by minimizing the need for repairs or replacements.

Ultimately, the importance of a quality beer bottle capping machine cannot be overstated. From preserving the freshness of your beer to streamlining your bottling process, a reliable capping machine is an essential tool for any brewery. By considering factors such as compatibility, automation, and durability, you can choose the best machine for your brewing needs and ensure that your beer stands out in a crowded market.

- Factors to Consider When Selecting a Beer Bottle Capping Machine

When it comes to bottling your own beer, one of the most crucial pieces of equipment you'll need is a beer bottle capping machine. Not only does a good capping machine ensure a tight seal on your bottles, but it also saves you time and effort in the bottling process. However, with so many options on the market, it can be overwhelming to choose the best one for your needs. In this comprehensive guide, we will delve into the factors you should consider when selecting a beer bottle capping machine.

First and foremost, you need to consider the type of capping machine that will best suit your needs. There are two main types to choose from: manual and automatic. Manual capping machines are more affordable and suitable for small-scale operations, while automatic machines are faster and more efficient for larger production batches. Consider the volume of beer you plan to bottle and choose accordingly.

Next, consider the size of the bottles you will be capping. Different capping machines are designed to accommodate various bottle sizes, so make sure the machine you choose is compatible with the bottles you plan to use. Additionally, consider the type of caps you will be using – for instance, crown caps or screw caps – and ensure the machine is capable of handling them.

Another important factor to consider is the construction and durability of the capping machine. Look for a machine that is made of high-quality materials, such as stainless steel, that is built to withstand the rigors of frequent use. A durable machine will not only last longer but will also ensure a consistent and reliable seal on your bottles.

Ease of use is another crucial factor to consider when selecting a beer bottle capping machine. Look for a machine that is easy to set up and operate, with intuitive controls and clear instructions. A machine that is user-friendly will save you time and frustration in the bottling process.

Finally, consider the price and overall value of the capping machine. While it may be tempting to opt for the cheapest option, it's important to balance cost with quality and features. Look for a machine that offers a good balance of price, performance, and durability to ensure you get the most value for your investment.

In conclusion, selecting the best beer bottle capping machine involves considering a variety of factors, including the type of machine, bottle size compatibility, construction and durability, ease of use, and overall value. By taking these factors into account, you can choose a capping machine that will meet your needs and ensure a successful bottling process for your homemade beer.

- Comparing Manual vs. Automatic Beer Bottle Capping Machines

Beer bottle capping machines are essential tools for any brewery looking to efficiently seal their bottles. Whether you are a small craft brewery or a large-scale production facility, choosing the right capping machine can greatly impact the quality and consistency of your bottled beer. In this guide, we will compare manual vs. automatic beer bottle capping machines to help you make an informed decision.

Manual beer bottle capping machines are simple, hand-held devices that require the operator to place the cap on the bottle and then manually press the capping mechanism down to seal the bottle. These machines are suitable for small-scale breweries or for homebrewers who only bottle a limited amount of beer. They are affordable and easy to use, making them a popular choice for those just starting out in the brewing industry.

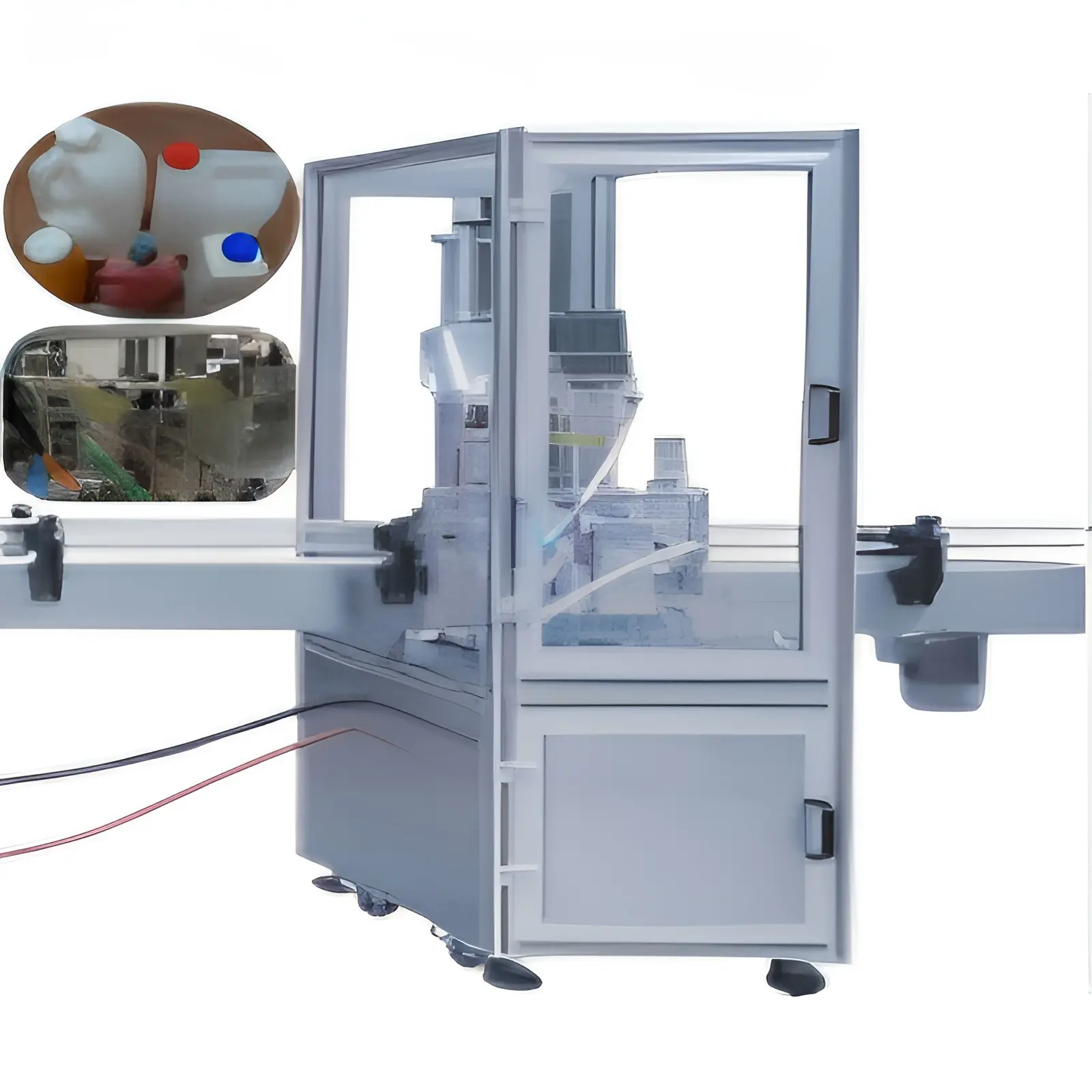

On the other hand, automatic beer bottle capping machines are more sophisticated and efficient. These machines use a conveyor system to align the bottles, place the caps on top, and then seal them with a pressurized mechanism. Automatic capping machines are ideal for large breweries that need to cap hundreds or even thousands of bottles per hour. They offer higher speed and consistency compared to manual machines, reducing the risk of human error and ensuring a tight seal on every bottle.

When choosing between manual and automatic beer bottle capping machines, there are several factors to consider. The first is production volume – if your brewery has a high output, an automatic capping machine would be more suitable to keep up with demand. However, if you have a smaller operation, a manual capping machine may be sufficient and more cost-effective.

Another factor to consider is the level of precision required. Automatic capping machines offer greater control over the capping pressure and consistency, resulting in a more uniform seal on each bottle. This is especially important for breweries that prioritize quality and want to ensure their beer remains fresh and carbonated during storage and transportation.

Cost is also a significant consideration when choosing a beer bottle capping machine. Automatic machines are more expensive upfront but can save time and labor costs in the long run. Manual machines are more budget-friendly but may require more manual labor and time to cap each bottle individually.

In conclusion, the choice between manual and automatic beer bottle capping machines ultimately depends on the specific needs and production goals of your brewery. Whichever option you choose, investing in a high-quality capping machine is essential to ensure the success and efficiency of your beer packaging process.

- Top Features to Look for in a Beer Bottle Capping Machine

When it comes to bottling your own beer, having a reliable beer bottle capping machine is essential. With so many options on the market, it can be overwhelming to choose the best one for your needs. In this ultimate guide, we will discuss in detail the top features to look for when selecting a beer bottle capping machine.

One of the most important features to consider when choosing a beer bottle capping machine is its capacity. Depending on the size of your brewing operation, you will need to determine how many bottles you need to cap per hour. Some machines can cap as few as 100 bottles per hour, while others can cap over 500 bottles per hour. It is important to choose a machine that can keep up with your production needs.

Another important feature to consider is the type of caps the machine can accommodate. Some machines are only compatible with crown caps, while others can also work with twist-off caps or even cork closures. Make sure to choose a machine that is compatible with the type of caps you plan to use for your beer bottles.

Durability is another key factor to consider when selecting a beer bottle capping machine. You want a machine that is built to last and can withstand the rigors of a busy brewing operation. Look for machines made from high-quality materials like stainless steel that are built to withstand frequent use.

Ease of use is also an important consideration when choosing a beer bottle capping machine. Look for a machine that is easy to operate and maintain, with intuitive controls and clear instructions. Some machines come with features like adjustable height and speed settings to make the capping process even easier.

In addition to these key features, there are other factors to consider when selecting a beer bottle capping machine. These include the machine's footprint, noise level, and power requirements. It is also a good idea to read reviews from other brewers to see how the machine performs in real-world use.

In conclusion, choosing the best beer bottle capping machine is an important decision for any brewer. By considering factors like capacity, cap compatibility, durability, ease of use, and other key features, you can find a machine that meets your needs and helps you bottle your beer efficiently and effectively. With the right machine by your side, you can focus on perfecting your brew and sharing it with others.

- Tips for Maintaining and Using Your Beer Bottle Capping Machine Efficiently

Beer bottle capping machines are indispensable tools for any brewery or home brewer looking to efficiently package their beer. In this ultimate guide, we will take a comprehensive look at how to choose the best beer bottle capping machine for your needs, as well as provide tips for maintaining and using it efficiently.

When selecting a beer bottle capping machine, there are several factors to consider. Firstly, you will need to decide whether you want a manual or automatic capper. Manual cappers are typically more affordable and suitable for smaller scale operations, while automatic cappers are faster and more efficient for larger production runs. Additionally, consider the size and shape of the bottles you will be capping, as not all machines are compatible with every type of bottle.

Another important consideration is the type of capping mechanism the machine uses. There are two main types: crown cappers, which use crowns (or caps) to seal the bottles, and twist cappers, which twist the cap onto the bottle. Crown cappers are more commonly used in the beer industry and are generally more reliable and cost-effective.

Once you have selected the right beer bottle capping machine for your needs, it is important to properly maintain it to ensure it continues to perform efficiently. Regularly clean and sanitize the machine to prevent any build-up of bacteria or debris that could affect the capping process. Check for any signs of wear or damage, such as loose or missing parts, and replace them as needed. It is also a good idea to lubricate the moving parts to keep the machine running smoothly.

When using your beer bottle capping machine, there are a few key tips to keep in mind to ensure efficient operation. Firstly, make sure the machine is properly adjusted for the size and type of bottle you are using. This will help prevent any mis-caps or leaks. Additionally, always use high-quality caps to ensure a proper seal on the bottles. Finally, take your time when capping the bottles to ensure each one is securely sealed.

In conclusion, choosing the best beer bottle capping machine is essential for any brewery or home brewer looking to efficiently package their beer. By considering the factors mentioned above and following our tips for maintaining and using the machine, you can ensure a seamless capping process and produce high-quality, properly sealed bottles of beer every time. Cheers to perfectly capped brews!

Conclusion

In conclusion, choosing the best beer bottle capping machine is a crucial decision for any brewery looking to streamline their production process and ensure the quality of their product. With 11 years of experience in the industry, our company understands the unique needs and challenges that breweries face when selecting equipment. By following the ultimate guide to choosing the best beer bottle capping machine, breweries can make informed decisions that will set them up for success in the future. As technology continues to advance, it is essential for breweries to stay current and invest in the right equipment that will not only meet their current needs but also grow with their business. Cheers to finding the perfect beer bottle capping machine for your brewery!