Streamlining The Packaging Process: The Benefits Of An Automatic Flat Labeling Machine

Are you looking to streamline your packaging process and boost efficiency in your operation? Look no further than an automatic flat labeling machine. In this article, we will explore the numerous benefits that come with investing in this advanced packaging technology. From increased productivity to improved accuracy, discover how an automatic flat labeling machine can revolutionize your packaging process. Join us as we delve into the advantages of this innovative solution and take your packaging operation to the next level.

- The Evolution of Packaging Technology: Automatic Flat Labeling Machines

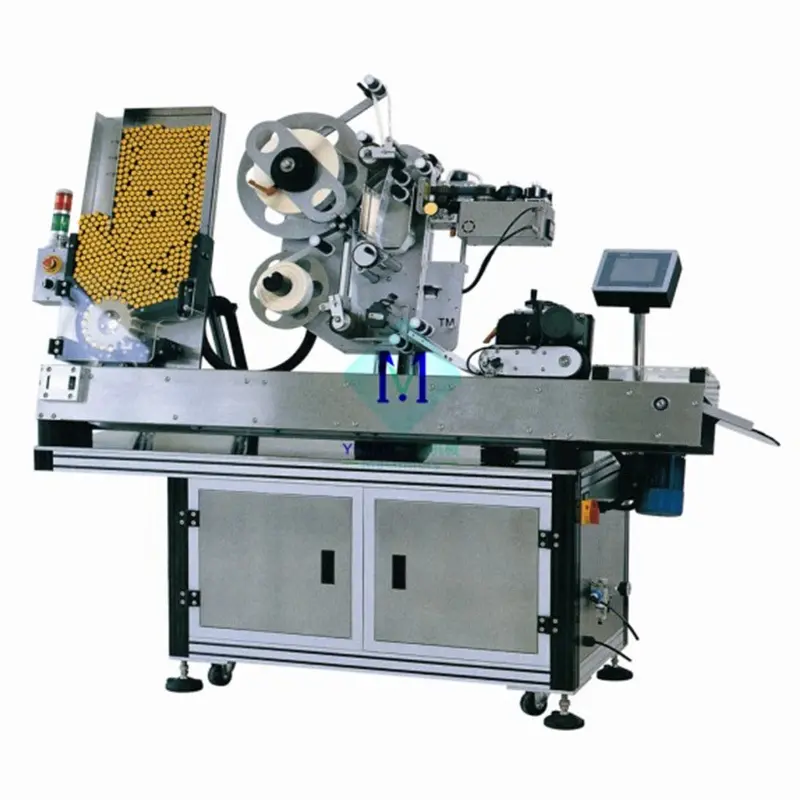

In today's fast-paced world of manufacturing and packaging, efficiency is key. One of the latest advancements in packaging technology is the automatic flat labeling machine. This innovative piece of equipment has revolutionized the way products are labeled and packaged, streamlining the process and improving overall efficiency.

The evolution of packaging technology has come a long way since the days of manual labeling. With the introduction of automatic flat labeling machines, manufacturers can now label their products with speed and precision, saving time and reducing labor costs. These machines are designed to apply labels to flat surfaces quickly and accurately, ensuring that products are properly labeled every time.

One of the main benefits of using an automatic flat labeling machine is the increase in production efficiency. These machines are capable of labeling hundreds of products per minute, significantly speeding up the packaging process. This not only saves time but also allows manufacturers to meet tight deadlines and fulfill orders quickly.

Another advantage of automatic flat labeling machines is their versatility. These machines can be used to label a wide range of products, from food and beverages to cosmetics and pharmaceuticals. They can apply both paper and film labels, as well as transparent labels, giving manufacturers the flexibility to meet various labeling requirements.

In addition to efficiency and versatility, automatic flat labeling machines also offer cost savings. By reducing the need for manual labor, manufacturers can cut down on labor costs and reallocate resources to other areas of their business. The high speed and accuracy of these machines also reduce the risk of errors, saving companies money in the long run.

Furthermore, automatic flat labeling machines are easy to operate and maintain. With user-friendly interfaces and minimal downtime for maintenance, these machines are a convenient and reliable solution for manufacturers looking to streamline their packaging process.

Overall, the introduction of automatic flat labeling machines has transformed the packaging industry, offering a more efficient, cost-effective, and versatile solution for labeling products. With their high speed, accuracy, and ease of use, these machines have become an essential tool for manufacturers looking to stay competitive in today's market. Automatic flat labeling machines represent the future of packaging technology, providing a way for companies to improve their efficiency and productivity in the ever-evolving world of manufacturing.

- Efficiency and Cost Savings: How Automatic Flat Labeling Machines Streamline Operations

In today's fast-paced manufacturing environment, efficiency and cost savings are crucial components of success. Companies are constantly searching for ways to streamline their operations and improve productivity. One key tool that can help achieve these goals is an automatic flat labeling machine.

Automatic flat labeling machines are essential in the packaging process as they can greatly increase efficiency and save costs. These machines are designed to precisely apply labels to flat surfaces such as bottles, boxes, and packages. By automating the labeling process, companies can significantly reduce the time and labor required for labeling, leading to increased productivity and lower operating costs.

One of the biggest advantages of automatic flat labeling machines is their ability to streamline operations. These machines are capable of labeling thousands of products per hour with unparalleled accuracy and consistency. This means that companies can significantly reduce the time and resources needed for labeling, allowing them to focus on other tasks and increase overall efficiency.

In addition to improving efficiency, automatic flat labeling machines can also save costs for companies. By automating the labeling process, companies can reduce the need for manual labor and minimize the chances of errors or mislabeling. This not only saves time and money but also helps avoid costly rework or product recalls due to labeling mistakes.

Furthermore, automatic flat labeling machines can help companies meet regulatory requirements and improve product quality. These machines are equipped with advanced technology to ensure that labels are applied correctly and meet industry standards. This can help companies avoid fines or penalties for non-compliance and maintain a high level of quality control.

Overall, investing in an automatic flat labeling machine can provide a wide range of benefits for companies looking to streamline their packaging process. From increased efficiency and cost savings to improved product quality and compliance, these machines can be a valuable asset for any manufacturing operation. By leveraging the power of automation, companies can stay competitive in today's market and take their operations to the next level.

- Improved Accuracy and Consistency: Enhancing Product Quality with Automated Labeling

In today's competitive market, manufacturers are constantly seeking ways to improve efficiency and product quality. One key aspect of the packaging process that can greatly impact both of these factors is labeling. While manual labeling processes can be prone to errors and inconsistencies, automatic flat labeling machines offer a solution that can streamline operations and enhance overall product quality.

One of the main benefits of using an automatic flat labeling machine is the improved accuracy and consistency it provides. Manual labeling processes are inherently prone to human error, resulting in incorrectly labeled products that can lead to customer dissatisfaction and potential recalls. By automating the labeling process, manufacturers can ensure that each product is accurately labeled according to specifications, reducing the risk of costly errors.

In addition to improved accuracy, automatic flat labeling machines also offer increased consistency in labeling. Manual labeling processes can vary from operator to operator, leading to inconsistencies in label placement and alignment. This can detract from the overall quality and appearance of the product, as well as create confusion for consumers. Automatic flat labeling machines ensure that each product is labeled consistently, regardless of who is operating the machine, resulting in a more professional and uniform end product.

Furthermore, automatic flat labeling machines can also enhance product quality by streamlining the packaging process. Manual labeling processes can be time-consuming and labor-intensive, requiring significant manpower to label products accurately and efficiently. By automating the labeling process, manufacturers can increase production efficiency and reduce labor costs, allowing workers to focus on other value-added tasks. This not only improves overall productivity but also ensures that products are labeled quickly and accurately, leading to faster turnaround times and increased customer satisfaction.

Another key advantage of using an automatic flat labeling machine is the flexibility it offers in labeling various types of products. These machines can be easily adjusted to accommodate different label sizes and shapes, as well as different packaging formats. This allows manufacturers to label a wide range of products with ease, without the need for multiple labeling machines or manual adjustments. This level of flexibility not only saves time and resources but also allows manufacturers to adapt quickly to changing market demands and product requirements.

Overall, the benefits of using an automatic flat labeling machine in the packaging process are clear. From improved accuracy and consistency to enhanced product quality and streamlined operations, these machines offer a cost-effective solution for manufacturers looking to boost efficiency and competitiveness in today's fast-paced market. By investing in an automatic flat labeling machine, manufacturers can not only improve their bottom line but also enhance their reputation for quality and reliability in the eyes of consumers.

- Adapting to Industry Trends: The Flexibility of Automatic Flat Labeling Machines

In today's fast-paced and ever-changing market, businesses are constantly looking for ways to stay ahead of the competition. One key aspect of this is adapting to industry trends, and one way to do this in the packaging process is by utilizing automatic flat labeling machines.

Automatic flat labeling machines have become increasingly popular in recent years due to their flexibility and efficiency in streamlining the packaging process. These machines are able to apply labels to flat surfaces quickly and accurately, making them ideal for a wide range of products including food and beverage, pharmaceuticals, and personal care items.

One of the key benefits of automatic flat labeling machines is their ability to adapt to industry trends. As consumer preferences and market demands change, businesses must be able to quickly adjust their packaging and labeling to meet these new requirements. Automatic flat labeling machines allow for easy customization, making it simple to switch between different products, label sizes, and designs.

Additionally, automatic flat labeling machines offer a high level of flexibility in terms of speed and accuracy. These machines are able to label hundreds of products per minute, ensuring a fast and efficient packaging process. They also have advanced technology that ensures precise label placement, reducing the risk of errors and improving overall product quality.

Another advantage of automatic flat labeling machines is their cost-effectiveness. While there is an initial investment required to purchase and set up these machines, the long-term benefits far outweigh the upfront costs. By streamlining the packaging process and increasing efficiency, businesses can save time and money in the long run.

Overall, automatic flat labeling machines offer a range of benefits for businesses looking to streamline their packaging process. From adapting to industry trends to improving efficiency and reducing costs, these machines are a valuable tool for staying ahead in today's competitive market. By investing in automatic flat labeling machines, businesses can ensure that they are able to meet the demands of consumers and maintain a competitive edge in their industry.

- The Future of Packaging: Maximizing Productivity with Automated Labeling Solutions

In today's fast-paced and highly competitive business world, packaging plays a crucial role in the success of a product. As consumers become more discerning and have higher expectations when it comes to packaging, companies are constantly looking for ways to streamline their packaging processes and maximize productivity. One of the key solutions that has been gaining popularity in recent years is the use of automatic flat labeling machines.

Automatic flat labeling machines are cutting-edge technology that revolutionizes the packaging industry. These machines are designed to apply labels to flat surfaces with speed and precision, eliminating the need for manual labeling which is time-consuming and prone to errors. By automating the labeling process, companies can significantly increase their productivity and efficiency, ultimately leading to cost savings and higher profitability.

One of the main benefits of using an automatic flat labeling machine is the speed at which labels can be applied. With traditional manual labeling methods, workers have to carefully apply each label one by one, which is a time-consuming process. In contrast, automatic flat labeling machines can apply labels at a much faster rate, allowing companies to label more products in a shorter amount of time. This not only increases productivity but also enables companies to meet tight deadlines and keep up with consumer demand.

In addition to speed, automatic flat labeling machines also offer superior accuracy and consistency. Manual labeling is prone to human errors such as misalignment and smudging, which can result in costly rework and product wastage. Automatic flat labeling machines, on the other hand, are equipped with advanced technology that ensures precise and consistent label placement every time. This not only improves the overall appearance of the product but also enhances brand reputation and customer satisfaction.

Furthermore, automatic flat labeling machines are versatile and can be customized to meet the specific labeling requirements of different products. Whether it's applying transparent labels, barcodes, or promotional stickers, these machines can handle a wide range of label types and sizes with ease. This flexibility allows companies to adapt to changing market trends and product variations without compromising on labeling quality.

Overall, the future of packaging lies in maximizing productivity with automated labeling solutions such as automatic flat labeling machines. By investing in this innovative technology, companies can streamline their packaging processes, increase efficiency, and ultimately gain a competitive edge in the market. As consumer expectations continue to evolve, it is essential for companies to embrace automation and technology to stay ahead of the curve and deliver superior products to their customers.

Conclusion

In conclusion, investing in an automatic flat labeling machine can greatly benefit your packaging process by increasing efficiency, accuracy, and productivity. With over 11 years of experience in the industry, we understand the importance of streamlining operations to stay competitive in the market. By embracing technology and automation, you can improve the quality of your products, reduce labor costs, and ultimately boost your bottom line. So why wait? Upgrade your packaging process today and experience the countless benefits of an automatic flat labeling machine.