Streamline Your Packaging Process With A Vertical Labeling Machine

Are you looking to streamline your packaging process and boost efficiency? Look no further than a vertical labeling machine. In this article, we will explore how this innovative technology can revolutionize your packaging operation and help you save time and money. Read on to discover the benefits of integrating a vertical labeling machine into your production line.

- Introduction to Vertical Labeling Machines

In today's fast-paced manufacturing industry, efficiency and accuracy are essential for keeping up with customer demands and maintaining a competitive edge. One crucial aspect of the packaging process is labeling, as it not only provides key information to consumers but also plays a significant role in branding and marketing efforts. To streamline this process, many companies are turning to vertical labeling machines.

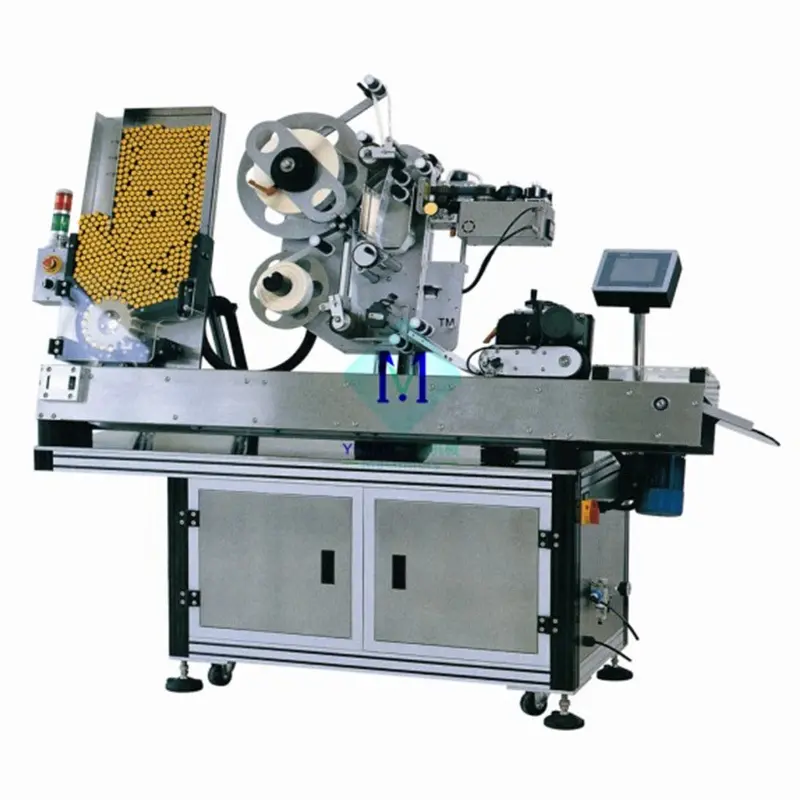

Vertical labeling machines are a type of labeling equipment that is specifically designed to apply labels to products in a vertical position. This can include a wide range of products, such as bottles, jars, tubes, and more. These machines are versatile and can accommodate various label sizes and shapes, making them suitable for different types of packaging.

One of the key advantages of vertical labeling machines is their efficiency. By automating the labeling process, companies can significantly increase their production output and reduce labor costs. These machines are capable of applying labels quickly and accurately, ensuring that products are labeled consistently every time. This not only saves time but also minimizes the risk of errors, which can be costly in terms of both time and resources.

In addition to efficiency, vertical labeling machines also offer benefits in terms of flexibility and customization. These machines can be easily adjusted to accommodate different label sizes and shapes, as well as various types of packaging. This means that companies can use the same machine for a wide range of products, making it a cost-effective investment in the long run.

Another advantage of vertical labeling machines is their compact design. Unlike other types of labeling equipment, vertical labeling machines take up less floor space, making them ideal for companies with limited space in their production facilities. This also makes them easy to integrate into existing packaging lines, allowing for seamless workflow and minimal disruption to operations.

In terms of ease of use, vertical labeling machines are designed with user-friendly interfaces and controls, making them simple to operate and maintain. This means that companies do not need to invest in extensive training for their employees to use these machines effectively. Additionally, many vertical labeling machines come with features such as automatic label detection and alignment, further simplifying the labeling process.

Overall, vertical labeling machines are an invaluable asset for companies looking to streamline their packaging process. With their efficiency, flexibility, and ease of use, these machines can help businesses increase their production output, reduce labor costs, and improve overall accuracy and consistency in labeling. As the demand for packaged products continues to grow, investing in a vertical labeling machine can be a strategic decision for companies looking to stay ahead in the competitive market.

- Benefits of Using a Vertical Labeling Machine for Packaging

In today's fast-paced and competitive market, businesses are constantly seeking ways to streamline their operations and improve efficiency. When it comes to packaging, using a vertical labeling machine can greatly benefit companies in various industries. This article will explore the numerous advantages of incorporating a vertical labeling machine into your packaging process.

One of the key benefits of using a vertical labeling machine is its ability to increase productivity. These machines are designed to apply labels to products quickly and accurately, reducing the time and labor required for manual labeling. This not only speeds up the packaging process but also allows employees to focus on other critical tasks, ultimately improving overall efficiency in the production line.

Furthermore, vertical labeling machines are versatile and can accommodate a wide range of product sizes and shapes. Whether you are packaging bottles, boxes, jars, or containers, these machines can be easily adjusted to apply labels seamlessly. This flexibility is especially beneficial for companies that work with multiple product lines or frequently change their packaging designs.

In addition to increasing productivity and versatility, vertical labeling machines also ensure precision and consistency in labeling. Manual labeling can often result in human errors such as crooked labels or misaligned placement. With a vertical labeling machine, labels are applied with precision every time, guaranteeing a professional and uniform appearance on all products. This not only enhances the overall aesthetics of the packaging but also helps to build brand credibility and trust with customers.

Another advantage of using a vertical labeling machine is its cost-effectiveness. While there is an initial investment required to purchase the machine, the long-term savings in labor costs and reduced waste from labeling errors make it a worthwhile investment for businesses. Additionally, the increased efficiency and productivity gained from using a vertical labeling machine can lead to higher output and revenue in the long run.

Moreover, vertical labeling machines are user-friendly and easy to operate, requiring minimal training for employees to use effectively. This means that companies can quickly integrate these machines into their packaging process without experiencing any major disruptions or delays. The intuitive design of these machines also allows for easy maintenance and troubleshooting, ensuring minimal downtime and maximum uptime for production.

In conclusion, incorporating a vertical labeling machine into your packaging process can significantly streamline operations and improve efficiency in your business. From increasing productivity and versatility to ensuring precision and consistency in labeling, the benefits of using these machines are undeniable. Not only do they save time and labor costs, but they also help to enhance the overall quality and appearance of your products. If you are looking to optimize your packaging process and stay ahead of the competition, investing in a vertical labeling machine is definitely worth considering.

- How to Choose the Right Vertical Labeling Machine for Your Needs

In today's fast-paced manufacturing industry, efficiency and productivity are key factors to success. One way to streamline your packaging process and increase productivity is by investing in a vertical labeling machine. By automating the labeling process, you can minimize errors, reduce labor costs, and improve overall efficiency.

When it comes to choosing the right vertical labeling machine for your needs, there are several factors to consider. The first step is to determine the size and type of products you will be labeling. Vertical labeling machines come in a variety of sizes and configurations, so it is important to choose a machine that is capable of handling the specific dimensions of your products.

Another important factor to consider is the speed and accuracy of the labeling machine. Some vertical labeling machines are capable of labeling hundreds of products per minute, while others may have a slower output. Depending on the volume of products you need to label, you may need to invest in a high-speed machine to keep up with demand.

In addition to speed and size, it is also important to consider the type of labels you will be using. Vertical labeling machines can handle a variety of label types, including paper, plastic, and metal labels. Some machines are even capable of applying labels to curved or uneven surfaces. Make sure to choose a machine that is compatible with the type of labels you will be using in your packaging process.

When selecting a vertical labeling machine, it is also important to consider the level of customization and flexibility it offers. Some machines come with adjustable settings that allow you to customize the label size, placement, and orientation. This can be especially useful if you have multiple products with different labeling requirements.

Finally, it is important to consider the overall cost and return on investment of a vertical labeling machine. While investing in a high-quality machine may require a larger upfront cost, the long-term savings in labor costs and increased efficiency can make it a worthwhile investment.

In conclusion, investing in a vertical labeling machine is a great way to streamline your packaging process and increase productivity. By considering factors such as size, speed, label type, customization, and cost, you can choose the right machine for your specific needs. With the right vertical labeling machine, you can improve accuracy, reduce labor costs, and ultimately, improve your bottom line.

- Steps to Implement a Vertical Labeling Machine in Your Packaging Process

In today's fast-paced world of manufacturing and production, efficiency is key. One way to streamline your packaging process and increase efficiency is by implementing a vertical labeling machine. These machines are designed to apply labels to products in a vertical orientation, making them ideal for a wide range of packaging processes.

Implementing a vertical labeling machine in your packaging process can have a number of benefits. Not only can it help to increase the speed and accuracy of labeling, but it can also help to reduce the need for manual labor and reduce the risk of errors. In addition, vertical labeling machines are versatile and can be used to label a variety of different products, from bottles and jars to boxes and containers.

There are a few key steps to consider when implementing a vertical labeling machine in your packaging process. The first step is to evaluate your current packaging process and determine how a vertical labeling machine can fit into the workflow. Consider the size and shape of your products, the volume of products being labeled, and any specific requirements for labeling, such as barcode scanning or lot tracking.

Once you have evaluated your current process, the next step is to research and select the right vertical labeling machine for your needs. There are a wide variety of vertical labeling machines available on the market, each with its own unique features and capabilities. Look for a machine that is easy to set up and operate, reliable, and able to handle the size and volume of products you need to label.

After you have selected a vertical labeling machine, the next step is to install and integrate it into your packaging process. This may involve working with the manufacturer or supplier of the machine to ensure that it is set up correctly and running smoothly. It is also important to train your employees on how to operate the machine safely and effectively.

Once your vertical labeling machine is up and running, be sure to monitor its performance and make any necessary adjustments to optimize its efficiency. Regular maintenance and cleaning will help to ensure that the machine continues to operate smoothly and label products accurately.

In conclusion, implementing a vertical labeling machine in your packaging process can help to streamline your operations and increase efficiency. By following the steps outlined in this article, you can successfully integrate a vertical labeling machine into your workflow and enjoy the benefits of faster, more accurate labeling. Take the time to evaluate your current process, select the right machine, and properly install and maintain it to maximize its effectiveness in your packaging process.

- Tips for Maximizing Efficiency and Accuracy with a Vertical Labeling Machine

Streamline Your Packaging Process with a Vertical Labeling Machine - Tips for Maximizing Efficiency and Accuracy

In the fast-paced world of packaging and labeling, efficiency and accuracy are key factors in ensuring a successful and profitable business. Vertical labeling machines have become an indispensable tool for companies looking to streamline their packaging process and increase productivity. These machines offer a quick and reliable way to apply labels to a wide range of products, from bottles and jars to boxes and cartons. In this article, we will discuss some tips for maximizing efficiency and accuracy with a vertical labeling machine.

First and foremost, it is important to choose the right vertical labeling machine for your specific packaging needs. There are many different types of vertical labeling machines available on the market, each designed for a specific type of product and labeling application. Before purchasing a machine, consider the size and shape of your products, the speed at which you need to label them, and any special requirements, such as barcodes or variable data printing.

Once you have selected the right machine for your needs, it is crucial to properly set it up and calibrate it for optimal performance. Make sure to follow the manufacturer's instructions for installation and operation, and take the time to adjust the machine settings to ensure accurate label placement. Proper calibration is essential for minimizing waste and maximizing efficiency, as even small errors in label positioning can result in costly rejections or rework.

In addition to proper setup and calibration, regular maintenance and cleaning are also essential for keeping your vertical labeling machine running smoothly. Make sure to clean the machine regularly, removing any dust or debris that could affect its performance. It is also important to check for worn or damaged parts, such as belts or rollers, and replace them as needed to prevent breakdowns and ensure consistent labeling quality.

Another tip for maximizing efficiency and accuracy with a vertical labeling machine is to optimize your labeling process. This includes organizing your workspace for maximum efficiency, using high-quality labels and inks, and implementing a consistent labeling workflow. Consider implementing automation and integration solutions to further streamline your packaging process and reduce the risk of human error.

Finally, it is important to monitor and analyze the performance of your vertical labeling machine regularly to identify any areas for improvement. Keep track of key performance indicators, such as labeling speed and accuracy, and use this data to make informed decisions about adjustments or upgrades to your labeling process. By continuously optimizing and fine-tuning your vertical labeling machine, you can ensure that your packaging process remains efficient and accurate, ultimately leading to increased productivity and profitability.

In conclusion, a vertical labeling machine is a valuable investment for companies looking to streamline their packaging process and improve efficiency and accuracy. By following the tips outlined in this article, you can maximize the performance of your vertical labeling machine and achieve optimal results in your packaging operations. Remember, efficiency and accuracy go hand in hand when it comes to labeling, so it is important to prioritize both aspects in your labeling process.

Conclusion

In conclusion, implementing a vertical labeling machine into your packaging process can greatly improve efficiency and productivity. With 11 years of experience in the industry, our company understands the importance of streamlining operations and maximizing output. By investing in a vertical labeling machine, you can automate the labeling process, reduce the risk of errors, and increase overall efficiency. This investment not only saves time but also enables your business to meet the ever-growing demands of the market. Make the smart choice to streamline your packaging process today with a vertical labeling machine.